NPL RENEW FAQ

NPL RENEW - FREQUENTLY ASKED QUESTIONS

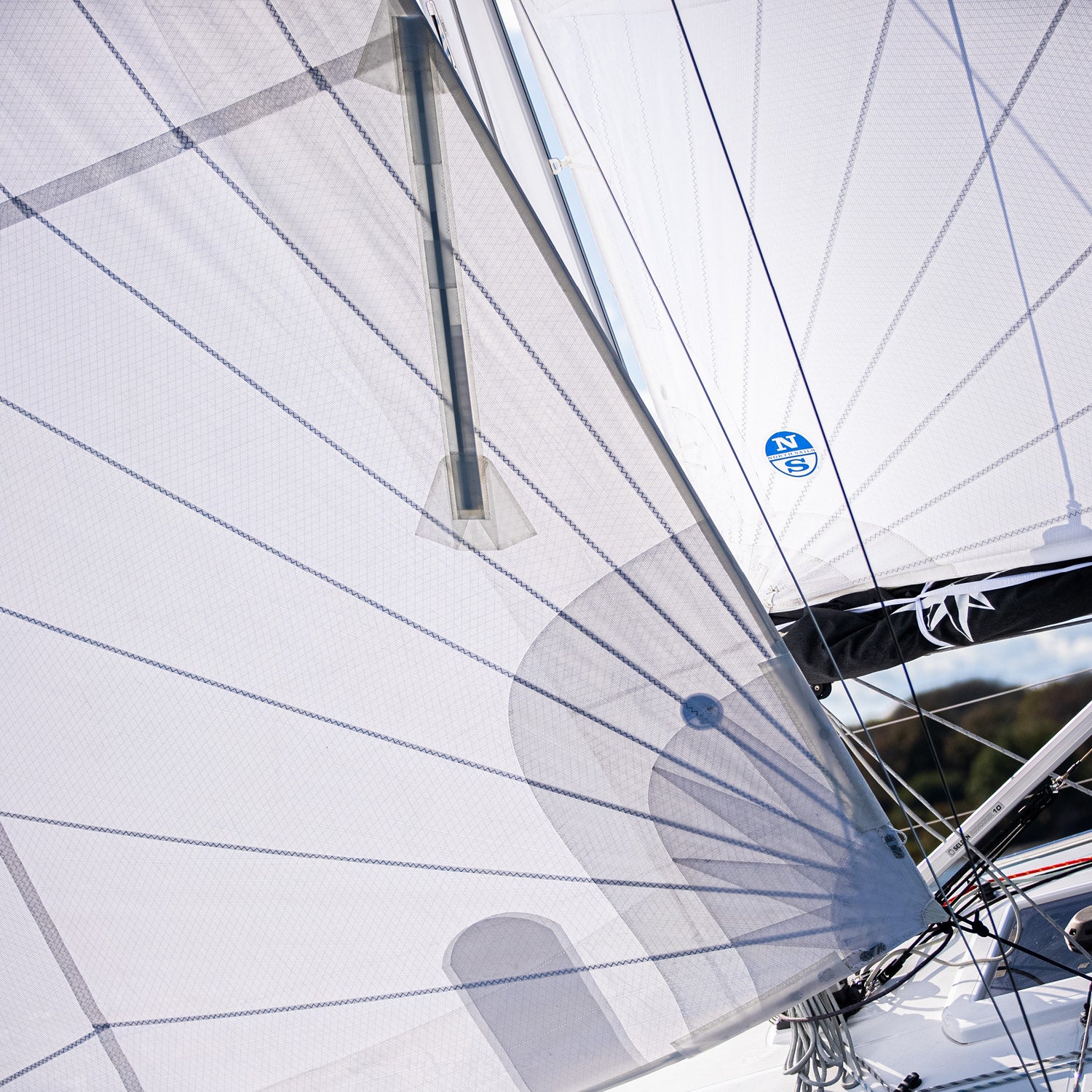

Introduced in January 2024 and available for cruising boats 25 to 45 ft, NPL RENEW is the start of a new and important shift for sailmaking towards a more sustainable sail that does not sacrifice performance and longevity.

RENEW, a North Panel Laminate features 90% alternative bio-based and recycled raw materials. Learn more about NPL RENEW with our FAQs from NPL RENEW Product Director Tom Davis.

Q: What is NPL RENEW?

A: RENEW, a North Panel Laminate, is a groundbreaking sail material composed of alternative bio-based and recycled raw materials. Specifically designed for cruising boats up to 45 ft, RENEW signifies a significant shift in sailmaking towards sustainable materials without compromising performance and longevity, aligning with North Sails' commitment to quality.

Q: Why is North Sails offering RENEW sail materials?

A: NPL RENEW represents North Sails' comprehensive initiative to seek and develop more sustainable materials that deliver sails without compromise in durability and performance. Since its inception, North Sails has been at the forefront of sailmaking technology, consistently introducing industry-changing advances. The quest for sustainability involves examining alternative fibers and other component materials, low-impact manufacturing, and circular material opportunities.

North Sails has committed to adopting Life Cycle Assessment (LCA) to learn about the ecological impact of all products and to establish goals for reducing waste and pollution. An important aspect of achieving these goals is to introduce more recycled content. By 2025, North Sails will implement a Responsible Product Scorecard for all products and will also establish measurable goals for circular products that can be recycled at the end of their lifecycle.

Q: How do you maintain performance and longevity with more sustainable materials?

A: Rigorous research and testing are fundamental to North Sails' approach to incorporating sustainable materials. We diligently evaluate evolving materials, ensuring authenticity with thorough testing in our state-of-the-art R&D Labs in Minden, NV (USA) and Sri Lanka. Trials on the water further assess performance and sail shape. The final raw material blend is optimized and manufactured at North Sails' own factory in Sri Lanka.

Q: When did North Sails start working on sustainable product innovation, and how did that lead to NPL RENEW?

A: NPL RENEW is the culmination of seven years of behind-the-scenes efforts. The journey began in 2017, resulting in a switch to a recycled polyester film in the NPL line in 2020. Subsequent innovations included sustainable yarn development, working with bio-based Dyneema made from wood pulp, and ongoing research into resins and glue systems. NPL RENEW is a testament to North Sails' commitment to responsible product innovation.

Q: NPL RENEW is available in two choices - standard and high-modulus. Can you explain these two versions of NPL RENEW?

A: NPL RENEW offers two versions - standard (SM) and high-modulus (HM). The standard version features recycled polyester, ideal for smaller boats. The high-modulus variant includes adding bio-based Dyneema yarn reinforcement for very low stretch and high strength, suitable for boats up to 45 feet.

Q: What do we mean by recycled and bio-based in NPL RENEW?

A: Recycled materials in NPL RENEW refer to turning finished products, like plastic bottles, otherwise bound for landfill or incineration, into raw materials for sailcloth. In this case, the product features multiple components made from 100% recycled materials: polyester film, polyester insert yarn, and woven polyester taffeta outer plies.

Bio-based involves using Dyneema fiber derived from wood pulp, providing an eco-friendly alternative to traditional methods involving oil extraction. Bio-based is not taking a product and recycling it. Instead, it's when you make ethylene from wood and then create ultra-high molecular-weight polyethylene. The normal way to make it, the way we've been making it for years, whether it's for a milk jug or a sailcloth, has been to pump oil out of the ground, and you refine it into... well, in this case, ethylene. Which you then polymerize into polyethylene. But with bio-based, our supplier starts with tree pulp products from Finland, which are then “distilled” into ethylene, and onward from there.

Oil and wood pulp don't seem like they would be in the same world, but chemically, you “just” need to get the same molecules to bond in the same “pattern". It's not unlike making good distilled whiskey - whether from barley, corn, rye, or wheat.

Leveraging this innovation showcases North Sails' commitment to sustainable practices and responsible product development.

Q: 90% alternative bio-based and recycled raw materials? What is the other 10%?

A: Three of four components make up the 90%. The fourth and final 10% is the resins and glue systems. We found that the types of resins that we, North Sails, use are incredibly durable, and we haven't yet found a good alternative that has a legitimate, more sustainable backstory. So far, the best choice is the long life of the tried and true resin system we use in our NPL and 3Di product lines.

We are continuing to test, trial, and work with different suppliers to find more sustainable solutions. We are confident North Sails will be the first to identify truly appropriate sustainable resin systems, and this will further enhance the sustainable build of RENEW.

We are continuing to test, trial, and work with different suppliers to find more sustainable solutions. We are confident North Sails will be the first to identify truly appropriate sustainable resin systems, and this will further enhance the sustainable build of RENEW.

Q: What sustainability credentials do the RENEW raw materials carry?

A: Our suppliers for recycled PET films, PET taffetas, and PET yarns are all certified by Bluesign, the gold standard for validation of sustainability claims in manufactured products. Every item carrying the Bluesign Product or Approved label has been manufactured to strict safety and environmental requirements. Bluesign partner brands include Nike, Patagonia, and The North Face. Click here to learn more about Bluesign.

The bio-based high modulus, Dyneema fiber life cycle assessment shows a considerable reduction in the carbon footprint versus conventional HMPE yarns. Bio-based Dyneema reduces five tonnes of CO2 per tonne produced, as compared to conventional Dyneema. The fiber is certified according to the ISCC International Sustainability & Carbon Certification to ensure compliance and traceability.

Q: Do RENEW sails look different?

A: The most noticeable difference is the bright whiteness that comes from using recycled polyester yarn in the external taffeta plies. Otherwise, RENEW sails maintain a similar appearance to traditional cruising laminates, featuring durability, craftsmanship, and stitching quality.

Q: What sail types is NPL RENEW available for?

A: NPL RENEW is available for most cruising mainsails, jibs and genoas designed for boats ranging from 25 to 45 feet. North Sails plans to expand the range in the coming years.

Q: How can I trust North Sails to build a great cruising sail? Aren't you primarily focused on racing and superyacht sails?

A: North Sails is renowned for its success in racing and superyacht sails, but did you know the company has been the world's largest cruising sailmaker for decades? The experience gained in building sails for around-the-world racers and superyachts directly contributes to the durability and quality of all cruising sails. North Sails' dedication to cruising, combined with lessons learned from diverse sailing experiences, ensures the creation of exceptional cruising sails.