SAILS ENGINEERED FOR FAST AND DESIGNED TO LAST.

The unique sail requirements for Southern Ocean racing. At North Sails, our focus is on the performance of the sails that power this journey.

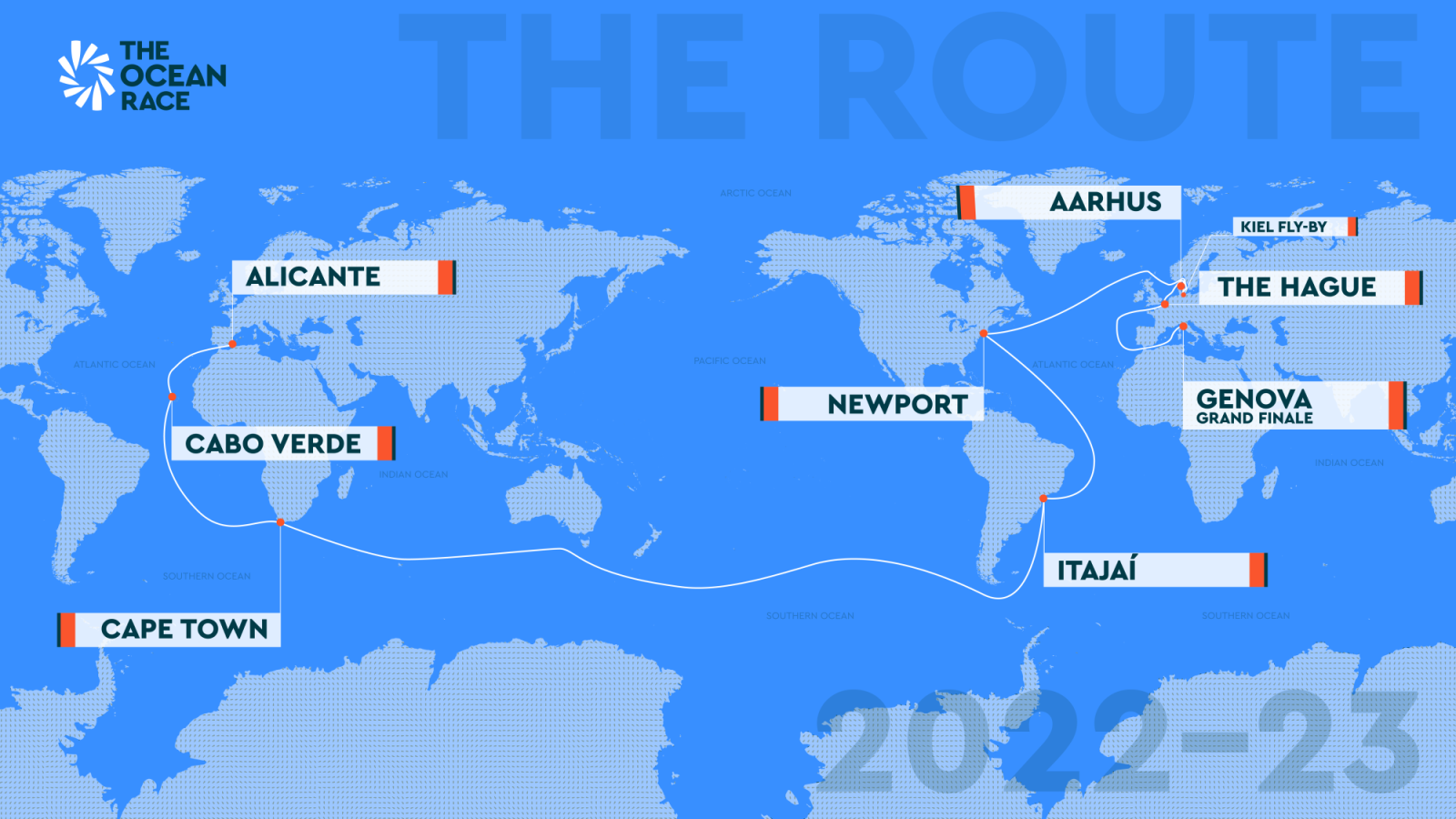

The Ocean Race fleet is sailing the longest leg of this race – 14,672 miles/23,613 kilometers from Cape Town to Itajai, Brazil – there are many questions about how the teams and their equipment will endure this amazing passage three-quarters of the way around the world in some of the planet’s harshest conditions of the notorious Southern Ocean. At North Sails, our focus is on the performance of the sails that power this journey.

The areas from 40 degrees south to the Antarctic Circle are known as the Roaring Forties and the Furious Fifties and have the strongest average winds found anywhere on earth. Wind speeds generated by the cyclonic storms that surge eastward through the area can reach up to 70 knots. When hitching a ride like this, the goal is to ride the storm downwind for as long as possible. That means long days, week after week, of dealing with screaming winds and massive white topped rolling waves while enduring a sail-stacking marathon gybing down the ice limit.

Southern Ocean sailing is what many sailors crave to experience firsthand. It’s high-speed, high-adrenaline sailing that you cannot experience anywhere else. But it’s proven to be punishing on the crews and their boats that venture into those deep latitudes.

As a gauge of just how remote this area is, during Leg 3, The Ocean Race fleet will pass close to Point Nemo – coordinates: 48°52.6′S 123°23.6′W – which, at 1,670 miles (2,688 kilometers) from the nearest piece of land, is officially the most remote spot on the planet.

Sail too cautiously, and the fleet will leave you behind, but pushing too hard can result in broken sails or equipment – or worse.

The Ocean Race rules allow each team to carry up to eight sails per leg (including a storm jib) and twelve in total for the race. Thus a team’s selection of sails is essential to optimize performance and balance, preserving their sails throughout the race.

A typical leg inventory consists of a Mainsail, A3 masthead gennaker, masthead A2 spinnaker, masthead Code 0, fractional Code 0, J2 headsail, J3 headsail, and a Storm Jib. When heading to the Southern Ocean, most teams will substitute their A2 for a high breeze running sail.

View this post on Instagram

Four of the five competing IMOCAs chose to carry North 3Di sails, with 3Di Helix headsails sails on furlers.

Helix furling sails are critical to a modern IMOCA inventory detail because the boat’s one design rig, initially engineered for a non-foiling boat with a righting moment of 25t.m, can now develop 40t.m. Helix with load-sharing helps manage that 40% step-up in power by transferring tack-load into the luff structure, thus reducing the total load without compromising the luff sag.

Helix sails also forgo a cumbersome anti-torsion cable in favor of a lighter, more agile, and easier-to-handle Helix Furling Cable, a feature that offers a new mode for sail trimmers. North designers engineer the bespoke furling cable and the Helix luff structure to work harmoniously. As trimmers increase or decrease the tack load, the cable acts like a cunningham, affecting the sail shape (flattening or deepening) and moving the draft fore and aft to extend a sail’s range.

Gautier Sergent, Ocean Race sail designer of record and Head of North Sails R&D, explained the considerations when creating sails for a fully-crewed Ocean Race IMOCA and how it differs from a solo, non-stop around the world Vendée Globe.

“You have to look at The Ocean Race as four separate races,” he said, “with optimization strategies for each section.”

- The northern and southern Atlantic with the doldrums and trade winds, mostly downwind or broad-reaching, and then the tricky light wind and changing breeze in the doldrums

- The Southern Ocean, with its high breeze and big seas downwind

- The Transatlantic leg from Newport, Rhode Island, back to Europe. Depending on the weather, this leg can be similar to the Southern Ocean or feature tighter reaching angles

- The short legs around Europe are coastal sprints constrained by geography and subject to the sea breeze. These sprints are where pure VMG or one sail can make a difference.

“When planning the sail strategy for the overall race, we try to find four distinct combinations of eight sails to match the expected conditions.”

“There has been tremendous effort put in by the teams and their project designers to model each leg in advance. North 3Di allows for immense flexibility in meeting the correct performance/durability balance by using custom 3Di tapes in varying densities to build the sail structure. North Sails designers calculated this with thorough load analyses coupled with a wealth of experience to anticipate the real-life scenarios that only occur in the open ocean.”

“Working with our team and our tools, North aero-engineers can advise on what sails to focus on, how they are sized and designed, and the appropriate sail structure. And because this around-the-world race has stopovers, there’s an opportunity to recut up to 25% of the sail area to make further optimizations for each leg.”

Sergent and former Volvo Ocean Race Boatyard Sail Loft manager Nathan Quirk admit these full-crew teams have the stamina and will be able to push the sails beyond the limits we’ve seen before in the traditionally short-handed IMOCA.

“The full-crewed teams have the manpower to trim sails more actively and will do so more aggressively to eke out every possible knot of boat speed,” explains Sergent. “Accordingly, we can design a less forgiving, maximum performance sail by adapting both the shape and construction compared to those for solo sailors.”

Quirk also points out that just as in the previous race sailed in one design Volvo 65s with all teams having the same 3Di sails, there may be some variance in wear and tear depending on how the teams handle their sails.

“We had some sails come to us in the previous race stopovers that were near-new and others that were pretty beat up,” he said. “You’d have wondered how they were in the same race.” Quirk and his team did, however, notice a correlation in sail condition with results: the teams that did well generally took better care of their sails. Just sayin’…

Nonetheless, when 3Di sails are damaged, Quirk and his team have helped develop techniques using strong, durable adhesives and repair materials that can be deployed even on board in wet conditions. And should there be a decision to re-shape a sail for better performance, Quirk explained that 3Di construction enables a surgical-like procedure to amend the sail’s shape.

“3Di is unlike any sail technology,” he explained, “where we can open up the materials, add what we want to improve the shape and strength, and re-bond it together into a near-new recut sail, similar to a boat repair. This expands the life and performance of an existing sail without using a new one from the limited inventory. Additionally, because a 3Di sail structure is engineered with multiple tapes in many directions, damage to these sails is often localized and the sail will maintain the overall integrity.

An intriguing aspect of 3Di applied to the IMOCA compared to the Volvo 65s is the incredible foil-borne high-speed performance, where boat speeds of 25-30 knots are not unusual. But as Sargent points out, while conventional notions of high-speed sail design infer flat sail shapes, the Ocean Race entries have more built-in power than one would expect.

“The IMOCAs produce incredible speeds while foiling,” he says. “But in big seas, they can also punch into the back of waves and almost come to a stop, needing to re-accelerate to get back on the foils. We use Helix sails to exploit all available power from the sail plan. Helix sails carry across a wider range and, with active trimming, can morph sail shape converting gust into thrust.”

Sergent says fine-tuning this balance depends on each boat’s foil and hull behavior. Therefore careful studies powered by North Sails’ decades of experience, thousands of project case studies, and the North Design Suite are run to optimize each sail design and understand its predicted behavior within the race’s broad range of conditions.

“We work hand in hand with the sailing and design teams from the outset of a project to engineer sails that match the targeted boat behavior and how the skipper intends to sail. Each team will play to their strengths and we design for where they want to outperform others; fast and furious in the Southern Ocean, through the transition zones, etc. One can not be the best in all conditions; it is still a matter of choice and decisions.”

Sergent and Quirk both say the Ocean Race continues to provide valuable insights into the future development of North Sails products and a further understanding of how their sails behave in the field. “North Sails is privileged to work on these projects and collect direct feedback from the best sailors in the world. This intimate feedback loop impacts our future products, design tools, and the next generation of sail designers which in turn benefits all North customers.”