A FIRST-HAND REVIEW OF 3Di NORDAC

A FIRST-HAND REVIEW OF 3Di NORDAC

Sail deliveries, fittings, and sea trials with North Sails expert Bill Fortenberry

Being a part of the 3Di NORDAC product development team, I was excited to spend some time this winter sailing in the Caribbean with our final version sails. The project is two years in development, involving a bunch of great people working through some interesting problems, all with a goal of redefining the Dacron cruising sail. An added bonus was including my family over a long birthday weekend! It promised to be a fun trip both personally and professionally.

On the plane heading down to BVI, I kept asking myself, “How we are going to extend the trust we have in this product to our customers?” Internally, we know the 3Di success stories well – around the world race durability, record-setting performance and the product’s hard earned approval in the highly demanding Superyacht arena. We trust 3Di and we also trust the science. Polyester is a nearly perfect fiber for cruising sails and, as predicted, applying modern manufacturing technology has resulted in a stronger sail with more permanent shape. Still, gaining the trust of skeptical cruising sailors, who may well be satisfied with cross-cut sails of woven polyester, was on my mind.

This trip had some logistical challenges. The idea was to put our final versions to the test in Caribbean climate. Further, we wanted them on charter boats where we know sails get regularly abused. The plan was eight sails, installed on four boats, all on different islands. As a lifelong sailmaker, the anxiety of delivering sails and running into problems, such as sails not fitting or not arriving when and where we expected, has never left me. The number of sails, the importance of the project and the normal challenges of operating in tropical islands hightened my normal nervousness. Thankfully, a few days later, I was relieved to sit back with a rum drink knowing all of the sails fit and functioned properly – it was now time to go sailing.

A lot of my concerns about building trust were relieved during the sail fitting process. When it comes to understanding quality, first-hand experience is invaluable. While removing the charter sails and installing the 3Di NORDAC sails, I was reminded how heavy Dacron sails can be and how challenging it can be for one or two people to handle them. We have engineered 3Di NORDAC to weigh the same as comparable woven sails, so there was no real difference in picking up, moving flaking or folding the sails. However, the word “bulletproof” came to mind. No one will confuse 3Di NORDAC as a racing sail. Their inherent toughness, along with the familiar look and feel of Dacron will be reassuring to cruising sailors who are concerned with durability.

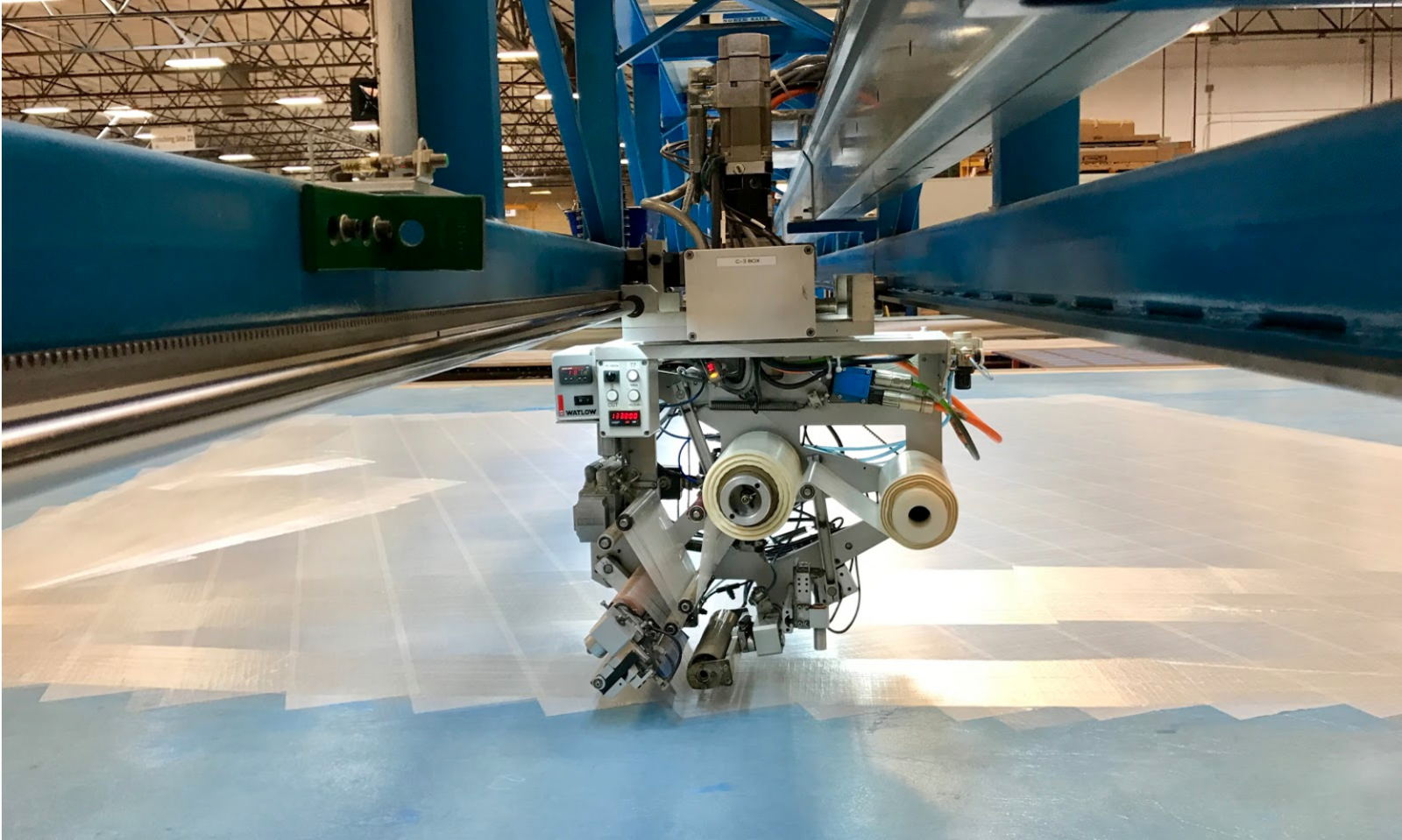

While the sails do have the basic look and feel of Dacron, there are some important distinctions. First, there are no seams. Composite sails built on full-size 3D molds are truly stunning to see and use. Perfect sail shape that persists in a range of wind conditions is a hallmark of 3Di sails. I kept thinking: we will no longer have to answer the most popular question from cruising sailors at boat shows, “How many rows of stitching do you use?” Answer: none.

Another distinction of 3Di NORDAC is the integration of features like batten pockets and reef points within the sail, reducing the amount of patching and sewn-on parts. The extra strength is applied exactly where it is needed, with the right amount in exactly the right orientation. The sails are stronger as a result.

Once sailing, I was reminded how reefed sail shape is another key distinction of 3D molded composite sails. The reef positions on mainsails and headsails have the reefing structure internal to the sail and aligned perfectly with the sail loads. Reefing most sails is a compromise in performance. Sailing with reefed 3D sails is a welcomed pleasure.

Beyond the differences in sail construction is the difference in performance. It takes fewer adjustments to control the sail power of molded sails. They react as you expect and part of the fun is actively being engaged in sailing the boat to its potential. Rather than sitting back and enduring the ride, the cruising experience is way more enjoyable when you participate in performance. With sails that stretch less, trimming and sail controls make a difference. Pulling on the backstay, easing the traveler or adjusting your jib car will all have the intended result in your sail. The result is a boat that moves through the water more efficiently with better motion. Your crew will certainly appreciate less heel and pitching, and you will enjoy steering more with less helm and leeway. Making sailing fun and enjoyable is a key benefit of great cruising sails.

Now, I was even more confident in our product, and luckily I got the chance to share my excitement with a client. Steve and Joy Frederick have sailed their Beneteau First 42 around the Caribbean for 15 years, and they planned to meet us in Virgin Gorda for some sailing. They are outstanding sailors, whose experience and lifestyle made them great test pilots for 3Di NORDAC. In a recent conversation, Steve recalled their first passage with the new sails,

“On our first stiff upwind sail was from St. Maarten to Antigua. Under a single reefed main and roller-reefed Genoa, we were punching through 6-foot seas at 7.5 knots with a 35-degree apparent wind angle. That’s not too shabby for a 30-year-old performance cruiser!”

After two weeks of sailing with family, friends and other North Sails cruising experts, a final theme came to mind: familiarity and reliability. As you use your equipment, you gain confidence. It did not take long to develop confidence in these sails. Seeing the stability of the sail shape while pounding through waves in the open ocean was a testament to the engineering behind 3Di NORDAC, and the complete transformation of cruising sails on the market today. Cruising sailors can now expect more from their sails, and as my friend, Tim Murphy from Cruising World magazine likes to say, “Sailboats were made to be sailed.”