GRAND PRIX STATION

GRAND PRIX STATION

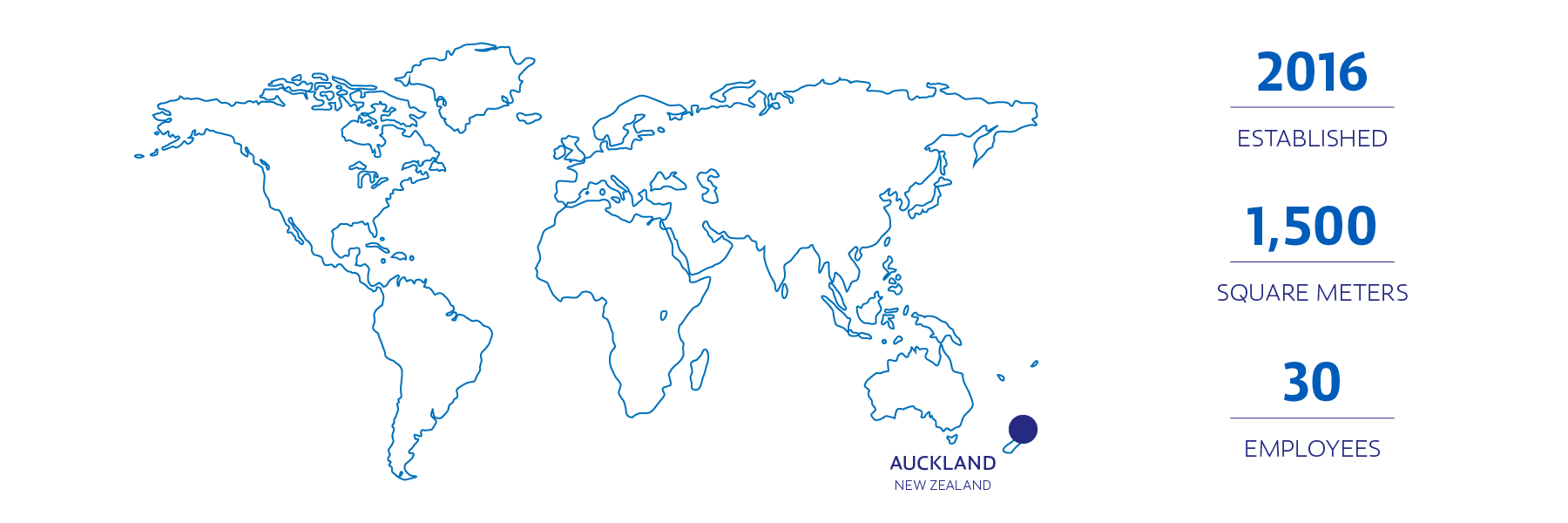

Production Profile: Auckland, NZL

Auckland holds a special place in the heart of sailing. Known as New Zealand’s yachting hub, this urban city’s affinity for the waterfront has welcomed premier sailing events to its shores time and time again. Thanks to deep roots in the America’s Cup, local sailing fans may be the most devout in the world and the team at North Sails New Zealand is no exception; the loft has found itself at the heart of the action with each Kiwi Challenge. By drawing from this experience, and spending many hours on the water, this tight-knit group has developed a knack for Grand Prix sailmaking and is now the go-to loft for professional teams from around the globe.

Loft manager Guy Hewson has a wealth of top-level sailmaking experience. After working as a sailmaker for Team Germany in the 2007 America’s Cup, Guy took professional sailing and boat captain roles all over Europe. This led him to the Louis Vuitton World Series, where he worked for Mascalzone Latino and Team New Zealand. He moved permanently to New Zealand in 2011 and soon took a position with North Sails as a senior sailmaker. In 2016, Guy began managing the North team out of a new location in Glenfield.

The Glenfield loft offered more space and the opportunity to design a workflow from scratch. Guy led the optimization of the new facility by accommodating the needs of each department – from upwind finishing to one design to downwind production. The result is a smart space boasting new efficiencies and flexible systems.

“We often need to operate service jobs alongside production,” said Guy, “and generally need options for managing multiple projects in the same space. One solution is we set up an A-frame furling system that accommodates luff lengths up to 60 meters, which is especially helpful when the Superyachts are in town and need service.” The team is also equipped with North’s signature rotating sewing pits and a few must-haves such as a plotter and cutter.

The strongest asset of the loft, Guy says, is the staff.

“Our loft is unique due to a long history of producing Grand Prix sails for teams in the Volvo Ocean Race, America’s Cup, TP52, and top competing one design classes. The majority of our sailmakers are great sailors, which gives them an expertise that bridges on-the-water performance with the work they do in the loft.”

Guy’s lead sailmakers in the upwind and downwind departments each have 15 – 20 years of experience making sails. The total group is best represented by their top-quality work and enthusiasm for sailing.

“We like to have fun, whether it’s in the loft or on the race course,” Guy continued.“This is the best bunch of people I’ve ever worked with. There is good camaraderie among the staff, healthy banter on the floor, and we all like to socialize together.”

Over the din of ten TP52 sails in production, Guy explained they were on a tight timeline to finish a number of custom jobs for the fleet. “We work fairly closely with all the other North lofts. Often we take on this type of work because of our relationship with the Grand Prix teams and the amount of time we’ve spent in this area of the market.”

While North Sails lofts in Minden and Sri Lanka provide a steady supply of molded sail “blanks,” specialty lofts like Guy’s have the client relationships and handle finishing and order fulfillment. North Sails schedules production based on specialty skills, as well as capacity and a loft’s proximity to the client.

Operating on an island does make things more difficult. “We would love to have a 3Di plant in New Zealand!” Guy laughed. “Since we are a ways away from Sri Lanka and Minden we factor shipping time into pretty much everything we do. A lot of our suppliers for parts and hardware are also overseas, so we keep a close eye on inventory and make sure our stock levels are well maintained.”

The cool thing about sailing is that even the most remote places in the world can become central at the height of the season. And with the America’s Cup coming to town in a few years, Auckland is already experiencing a resurgence in the local market.

“The global North team has great collective knowledge,” Guy added. “It’s nice to know our clients will have the support of North Sails no matter where they decide to travel. Capacity-wise, we take comfort in knowing that everyone’s peak season is different and by working together we can keep the workflow more consistent.”

Looking ahead, Guy’s priority is to maintain steady growth by staying true to what New Zealand does best.

“Our priority is quality of work, while keeping things efficient and economic. North Sails 3Di is setting us ahead of the game and we are all proud of the finished sails coming out of our loft. I’m equally proud of the team behind them.”