THE CUTTING EDGE OF OFFSHORE

THE CUTTING EDGE OF OFFSHORE

Production Profile: Vannes, Brittany, FRA.

The French offshore market was as fervent as ever when the North Sails loft in Vannes opened its doors in 2004; the Vendée Globe was in full swing, Jean-Luc Van Den Heede soon set the record for “the wrong way around” on Adrien, and Dame Ellen MacArthur soon broke the eastabout, singlehanded circumnavigation record on B&Q. Extensive sailing know-how combined with an innovative marine trade, makes France unlike any other in the sailing world. True to form, the North Sails team in Vannes specializes in offshore sailmaking, especially those jobs fit for breaking records.

The Vannes loft is led by Eric Gallais-Hamonno, who found his way there through a love of sailing. “Our dedication to the product, especially in offshore sailing, makes us unique,” said Eric. “As long as there is a market in France, we will be here.” Perhaps this dedication is what keeps sailing heroes like Armel Le Cleach, Francois Gabart, and Jean Le Cam returning to North Sails, whether it’s to alter a used inventory or to conceptualize sails for their next ocean racing craft.

“It’s easier to love your job when your product is used to do incredible things,” Eric continued. “We work in a community that pushes the boundaries; our team is always talking with skippers about how to make the sails lighter, faster, more sexy, and we are proud to see our clients make headlines for performance.”

A typical day in Vannes will see new sails for professional programs (Multi 50, Ultime, or Figaro) finished alongside service jobs for cruising clients or local racers. The loft boasts diverse experience within a staff of 10, the majority with 10 – 15 years in the game. “Our sales team has a powerful casein the experience of our sailmakers and designers,” Eric said. “The team is tight-knight, positive and hard working.”

A wealth of expertise and proximity to sailing’s most demanding projects, makes Vannes a source of knowledge for North Sails and the loft’s experience grows with each new project.

North Sails recently formed a global Research and Development team in Vannes. The group is headed up by lead designer, Gautier Sergent, who’s experience spans multiple record breaking campaigns; most recently Francois Gabart’s MACIF Ultime, Thomas Coville’s Sodebo Ultime, and Francis Joyon’s Trimaran IDEC Sport. It’s hard to overstate the importance of a skipper’s relationship with their sailmaker for these projects. The North team in France works hard to support the sailors in their pursuit of extreme challenges, and repeatedly earn their trust with each new venture.

The French offshore sailing market is as competitive off the water as it is on the ocean. Eric says the biggest difference in winning orders came with the introduction of North Sails 3Di. “There are many reputable sailmakers in France – six or seven making IMOCA sails, which are one of our specialties. We have a strong position with North Sails 3Di. Since the product was introduced our market share in the IMOCA has risen from 35% to 60%, with five of the first six Vendée Globe finishers carrying North Sails in 2016.” Also, all of the Ultime Trimarans are racing with North Sails 3Di, and the product has an unprecedented track record when it comes to powering offshore records.

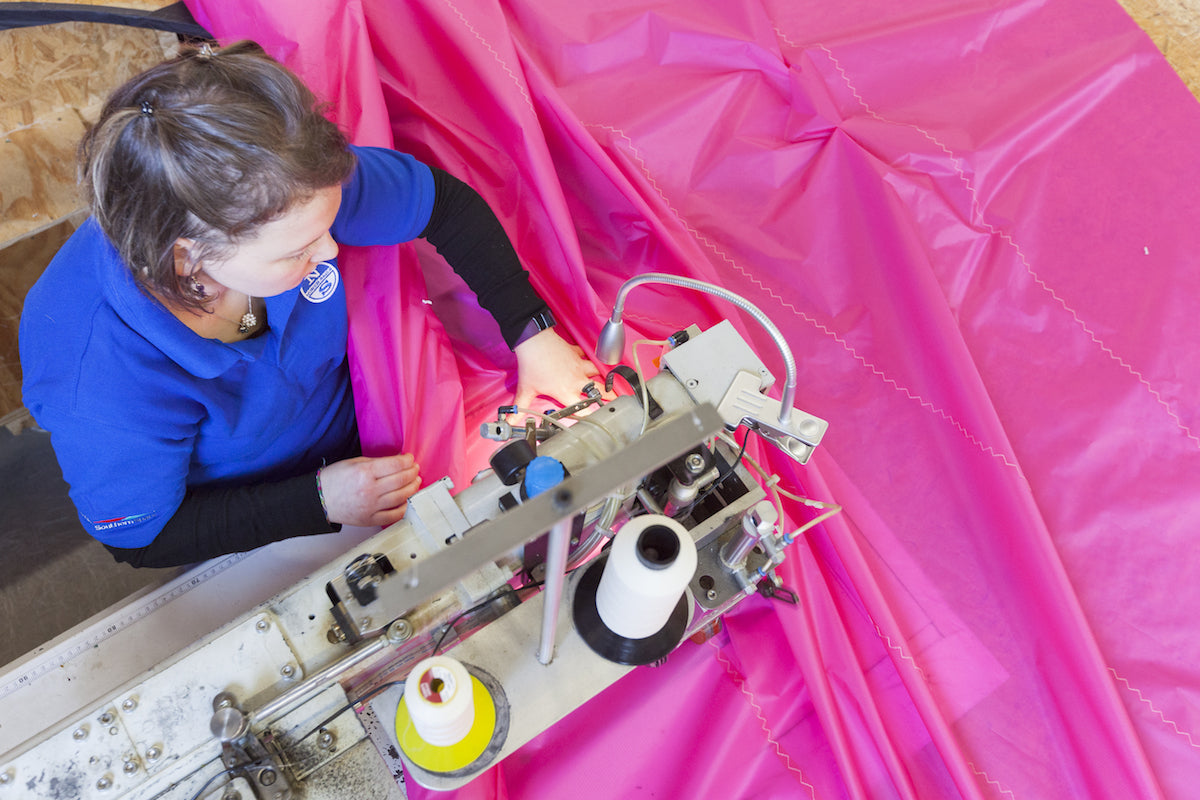

Vannes is one of seven production facilities worldwide wholly owned by North Sails. Minden and Sri Lanka are the only lofts with 3D sail technology and are a vital component to Eric’s operation. These lofts are responsible for production of all 3Di sail membranes. These membranes, or “blanks” are they’re call by the North lofts are finished by Eric’s team who add extra reinforcements, leech/luff tape, and hardware – before delivering them to the client. With the offshore market paramount, Eric’s team also taps Minden and Sri Lanka for help with cruising orders.

Since we are a global company now, we work with a central scheduler to liaise with all the lofts and distribute jobs, keeping the workflow steady for everyone. Sri Lanka especially is very good, and the North Sails Blue Book has implemented standards across all sites, to the point where we don’t need to manage the orders as closely.”

Today in Vannes, a single sailmaker can work independently on a new IMOCA 60 sail. Ten years ago the same job required two or three staff to maneuver the material smoothly through a sewing machine. North Sails 3Di also requires less finishing work. Finishing an IMOCA 3Di mainsail used to take 95 working hours; now it takes 85. (A traditional paneled main required 120 hours.) “The 3Di manufacturing process takes care of many parts and pieces simultaneously, by building things like batten pockets directly into the sail,” Eric said. “The result is a more durable, seamless construction that requires less manual labor. “

“My priority is to have happy customers – which means you deliver the sails on time, with all the requests completed fully. I have to say I am the most proud of my team. I wish I could spend more time with them on the floor! The people are really motivated. They are flexible and hard working – smiling through extra hours and having to share space with many projects happening simultaneously.”

When he does find the time to work alongside his team, Eric understands the roles reverse. “When I join them on the floor I begin by saying – Okay, what do you need me to do?”