THE NEW MELGES 40

North leads the way towards the new Melges 40

When a new high-performance boat comes on the market, the pressure is on to meet the expectations of everyone involved in the project: the designer, builder, class promoters, industry providers, media and – most importantly – the owners and crews. The higher the performance, the greater the expectations and the lower are the acceptable margins for error. New boats of this genre must be fast out of the box with little or no lead time available for testing and refinement: everyone wants one, so the first one built and launched will command great attention and must meet all expectations to provide that Wow factor needed to help launch the class into success.

The new Botin-designed Melges 40 is a perfect example of such a high-profile new design, with the global reputation of Melges on the line. Designer Marcelino Botin has said “Melges is a pure sailing legend, and this was an opportunity for us to design something very new and different. The design compliments the Melges brand, and upholds their top-quality ideals. With respect to their philosophy, we proposed a design that adopts and introduces new features and concepts. The Melges 40 creates a new benchmark for performance in the 40-foot range.”

Builder Max Waimer at Premier Composite Technologies said “For sure the Melges 40 is a new starting point in the sailing world. We share the same passion as Melges and Botin for creating not only an exceptional boat, but a very new, competitive racing experience. We truly have a common vision. The additional input from customers has made a big difference too. We put all of our production expertise and technology into the Melges 40.”

So, with this backdrop in mind, how is North meeting this demand to have the fastest sails ready for this exciting new one design?

The answer is in the process North has established to be intimately involved throughout the design development of the boat to gather the details on the rigging, spar set-up, and even the equipment on board to help advise on solutions that will benefit not only designing fast sails but also contribute to achieving the overall goals of the project. Participation in these formative stages helps in ensuring accuracy in not only the detailed sail geometries, but also in anticipating other important aspects of performance that affects the sails, such as crew work and the deck layouts that support their efficiency.

With this information the North Design Suite of sophisticated computational tools can be used to replicate the details of how the spar and sails integrate with the boat’s design to produce these expected levels of high performance. These tools have been used successfully and refined repeatedly for the past several years on a wide variety of boats, ranging from small keel boats to Maxis, so the process is well-proven and has led to North’s widespread success in all these classes.

Not only does this process help in the accuracy of sail design, but establishing a detailed knowledge base on the ground floor of a new project has other benefits, such as anticipating the content for a tuning guide that is ready to use at the first launch rather than having to wait for the completion of extensive sessions of sail testing.

Being a regular sail trimmer on Steve and Heidi Benjamin’s HPR 40 and now their TP 52 called SPOOKIE, North sail designer Chris Williams has a perfect perspective to the development and design process for the new Melges 40. “This boat is truly unique,” he says. “Besides having lots of sail area, the canting keel gives it a righting moment that is 20% greater than an HPR 40, so there is tremendous power and speed potential, and modeling the sails to drive its performance is not just using a variation of any existing designs.”

Williams explains more on the particulars:

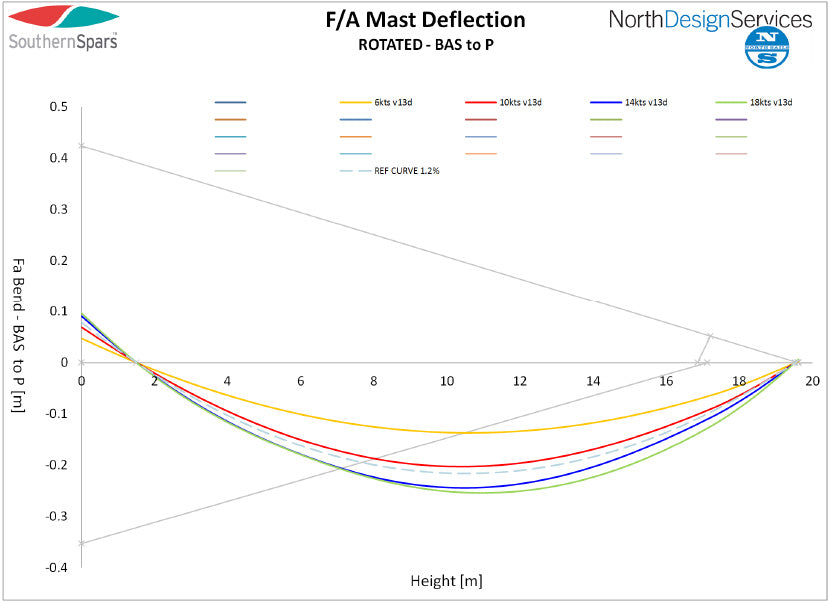

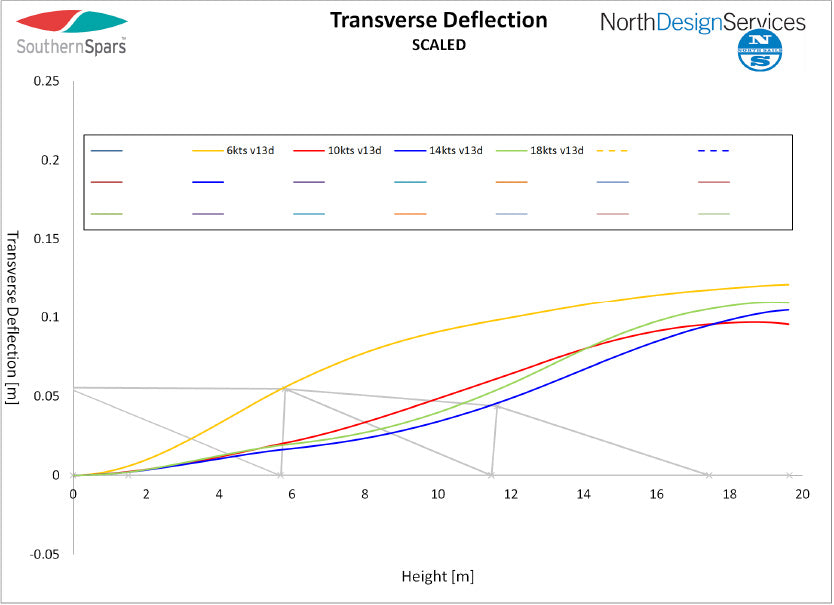

“We started work on this early with Southern Spars to identify the rig parameters so we could set up the sail plan properly using DesMan. On any boat the headstay characteristics are an important driver for jib design since it governs the luff tension, and for the Melges 40 we know there is no hydraulic ram for this adjustment, so we then knew the runner winch would control this for the boat. We then looked in detail at the runner set-up: the winch size and how much power it could generate, and the location of the runners and how efficient they would be in transferring the load to the headstay. We then urged the class design team to move the runners as close as possible to centerline so no moment would cause the spar to twist and throw off the tuning calculations.

“Once we recreated the spar’s properties in DesMan, we used Flow and Membrain to model our first test sails on the virtual yacht and start iterating towards greater refinement in the designs. This allows us to give some meaningful feedback to the class managers in which we helped establish some parameters for the One Design class rules and build specs for the yacht. An example of this is knowing the exact placement of the spar doubler: this ensures every yacht’s spars will work with any sail. Modeling the mast bends and jib trims through their ranges of different tunes and jack loads allows us to maximize the size and roach profile of the light air jibs and their batten placement relative to the available space in the foretriangle.”

After this crucial first step, the sail designs and their MemBrain modeling data are forwarded to other members in the North design team, who with their individual and collective experiences accumulated over dozens of similar projects can further refine their accuracy. For the Melges 40 these team members include Giovanni Cassinari, who is not only a North Sails sail designer and mainsail trimmer on the SuperSeries 52 Azzurra, but also will be racing on the new Melges 40 Inga; Marchino Capitani, another North Sails designer, coach of Azzurra, and an Inga team member; and Per Anderson, North Sails head of design.

“I’m sure the sails will be tweaked slightly with the overall goal of making sure that the first set built follow very closely to the ideas and design concepts of the group as a whole,” says Williams. “There are always many ways to skin a cat here, so the hard part is to make sure the sails are not designed by a committee so much as input and experience is given and shared by a group then correlated into a fast suite of sails.”

Finally, another important factor in the project was in working with the Melges 40 class to determine the optimal sail inventories needed for this boat through its range of performance, mindful that the class is interested in minimizing cost through allowing too many sails in the inventory and also being sensible their replacements. For the Melges 40 it was determined that 3 full-sized jibs was the best solution given not only the boat’s performance through the range of conditions but also their intended schedule of races and venues.

Part of this discussion is driven by the durability of the sails and their ability retain their performance shape through an acceptable lifespan. For the Melges 40 Williams says 3Di Raw materials will be used in the upwind sails, with a mix of tapes and their composition to be determined when the mold shapes and designs are finalized. He reckons that this brand new boat with its canting keel and massive sail area will have steep learning curves for the sailors, yet the accuracy and efficiency of the North Design Suite process will ensure that the first generation upwind sails and rig tuning guidelines from North will be at 95% of their ultimate level of development…this is highly encouraging news for those first few owners who want to come out of the box with fast results and remain fast as the class grows and develops.