2018 DESIGN MEETING DEBRIEF

2018 DESIGN MEETING DEBRIEF

North Sail Designers Combine Forces In Marblehead

In the final weeks of 2018, 23 North Sails designers from eight countries gathered in Marblehead, MA for a team debrief about progress in 2018 and what they’ll be working on in 2019. Hosted by JB Braun, this international brain trust talked through sail development, refinements to the North Design Suite, and 2019 baseline packages for race teams.

“Everybody said it was a tremendous meeting,” JB said when we caught up with him at his office a week later. “They felt that it was worth their time; not only valuable to the company, but also valuable individually.” Then he laughs. “Now we’re trying to figure out why.”

Mickey Ickert has an answer. “Face to face contact with the guys is good, as most of our work is remote,” he says. “Rather than presenting topics we worked through them, progressing as a whole group.”

Magnus Doole chimes in to define that progress in more detail. “As designers, we are encouraged to push the boundaries of both the design and structures of the sails we create; doing this as a team to pull our collective thoughts and reasoning was reinforced. I guess that’s ‘Go Beyond’!”

The North design team first came together for a global meeting in 2017. One year later, the core group—leading designers from key grand prix classes (TP52, Pac52, RC44, Mini Maxi, etc.), covering almost every time zone—were joined by some new blood for three days of collaboration and discussion. “Seeing these talented people – some a little younger,” Mickey says with a smile, “working ‘full noise’ on the same goals…it was refreshing, and everyone felt able to contribute.”

Brodt Taylor, a first-time attendee, agrees. “It flowed together really easily. We were constantly trying to move to the next thing, but at the same time, we didn’t let anything fall by the wayside.”

Technical Breakthroughs

The agenda included summarizing achievements from 2018 and stating goals for 2019. Magnus Doole says, “Each head of department was pushed to take the next step (whether defined or out there in the ether to be found).”

JB is more specific. “All the designs that we did, we made a spreadsheet analysis in the kind of detail that a sail designer would be interested in. We did the graphs…” he points to a model on his enormous computer screen. “Each one of these was done per class. Then the lead designer summarized what they did.”

Helix

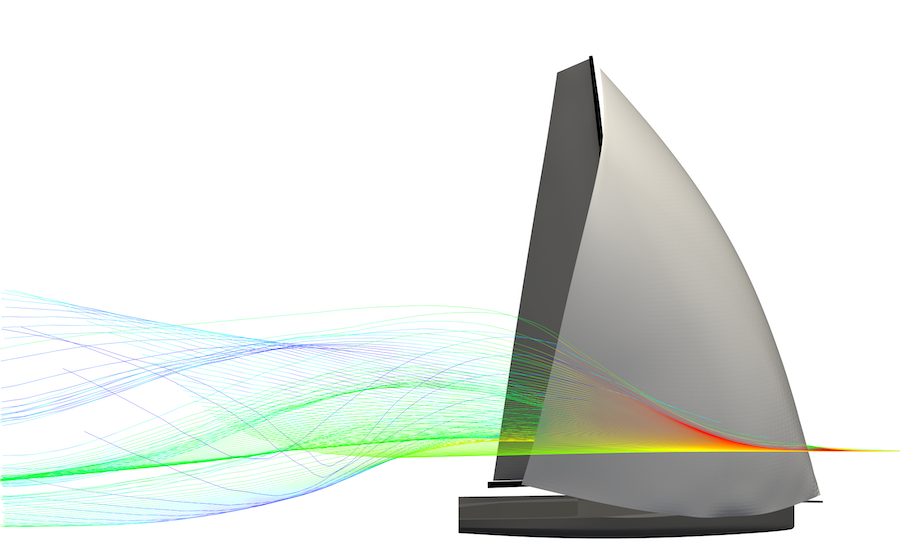

Another innovation reviewed by the design team was Helix sails, which use Load Sharing TechnologyTM to transition luff loads away from an anti-torsion cable and move it into with sail structure in offwind sails.

“We’re taking the structure of the sail, and supporting the luff,” JB explains. “That allows the luff to kind of rotate to weather.” As soon as you’re off the wind, a straight luff is no longer ideal. “You want positive luff curve to match the bend in wind from top to bottom. The entry is very nice, more consistent and even up and down. There is still a very small luff cable or rope, so you can adjust the tension.”

Load Sharing Technology coupled with the Helix Luff reimagines both roller furling downwind (Code Zero and A-3 style sails), reaching sails, and even may translate to some styles of upwind sails.

Baseline Packages: TP52

2018 marked the first year that baseline packages were offered in the TP52 class, which is on the leading edge of sail development. The approach worked well and 2019 packages are well under development. “The individual design teams can tweak from there—or just use the baseline designs,” JB says.

One significant breakthrough from this approach was the “bubble-less” jib. When designers spotted an area of extra drag created by narrow sheeting angles, they used the North Design Suite to tweak an already highly refined sail.“We used our tools and design to try to minimize this separation zone,” JB explained. The result was a faster jib.

Development continues for the 2019 TP52 season, of course. “We’re going to make a new layout and structure that’s going to be higher modulus and lighter than we did last year. We have a whole team set up to look at that.”

Once a design tweak like this proves successful in one class, it can be applied elsewhere. “Some things like tape density, or how the tapes are laid into the sail, that can go in and globally affect every single sail that North builds,” JB adds. “All this work filters back, even to your cruising customer, if it’s appropriate for that type of sail.”

Tool Tweaks

The North Design Suite is constantly improving as well. Michael Richelson, who heads up NDS development, attended the meeting. Mickey Ickert says, “Having the latest tool updates available with the guys who write the software right there is pretty powerful. It was an impressive mix of people working well together.”

A “Tremendous Success”

After three days of focused discussion in one room, JB says all 23 designers went home freshly inspired—though he admits the technical nitty-gritty may not be that exciting to anyone else. “We have talented designers that are passionate about making boats go faster. North Sails is providing us a unique opportunity, in software, machinery and organization, allowing us “designers” to operate at a super-high level, to get out and build sails, then get instant feedback from professional sailors. And this whole thing is happening right in front of them!”

“Passionate people, doing something that they love…” he shrugs. “They’re being heard, and they’re contributing to something bigger than what they’re doing individually. Maybe that’s why our meeting was such a tremendous success.”