THE REASON NORTH 3Di IS A MUST-HAVE

THE REASON NORTH 3Di IS A MUST-HAVE

By now, you've likely heard 3Di sails are the best, the fastest, the most durable, and the must-have sail technology. But why? What makes 3Di sails so unique? Keep reading as we deep dive and uncover the reasons.

NO FILM. NO DELAM

Mylar film is a versatile material with many uses; performance sails aren't one of them.

Mylar film is a versatile material with many uses; performance sails aren't one of them.

Mylar has drawbacks that make it undesirable for long-lasting, reliable sails. North Sails' zero Mylar 3Di construction method creates exceptionally durable sails that resist stretching, UV degradation, and, most importantly, delamination.

3Di sails hold their shape exceptionally well over time, even after extensive use. Without Mylar, there's no risk of premature breakdown, distortion, or extreme shape change due to delamination.

Because of zero Mylar construction, 3Di sails boast enduring shape and performance, resist stretch, UV damage, and harsh weather. This tougher construction ensures consistent, top-tier performance throughout the sail's lifespan.

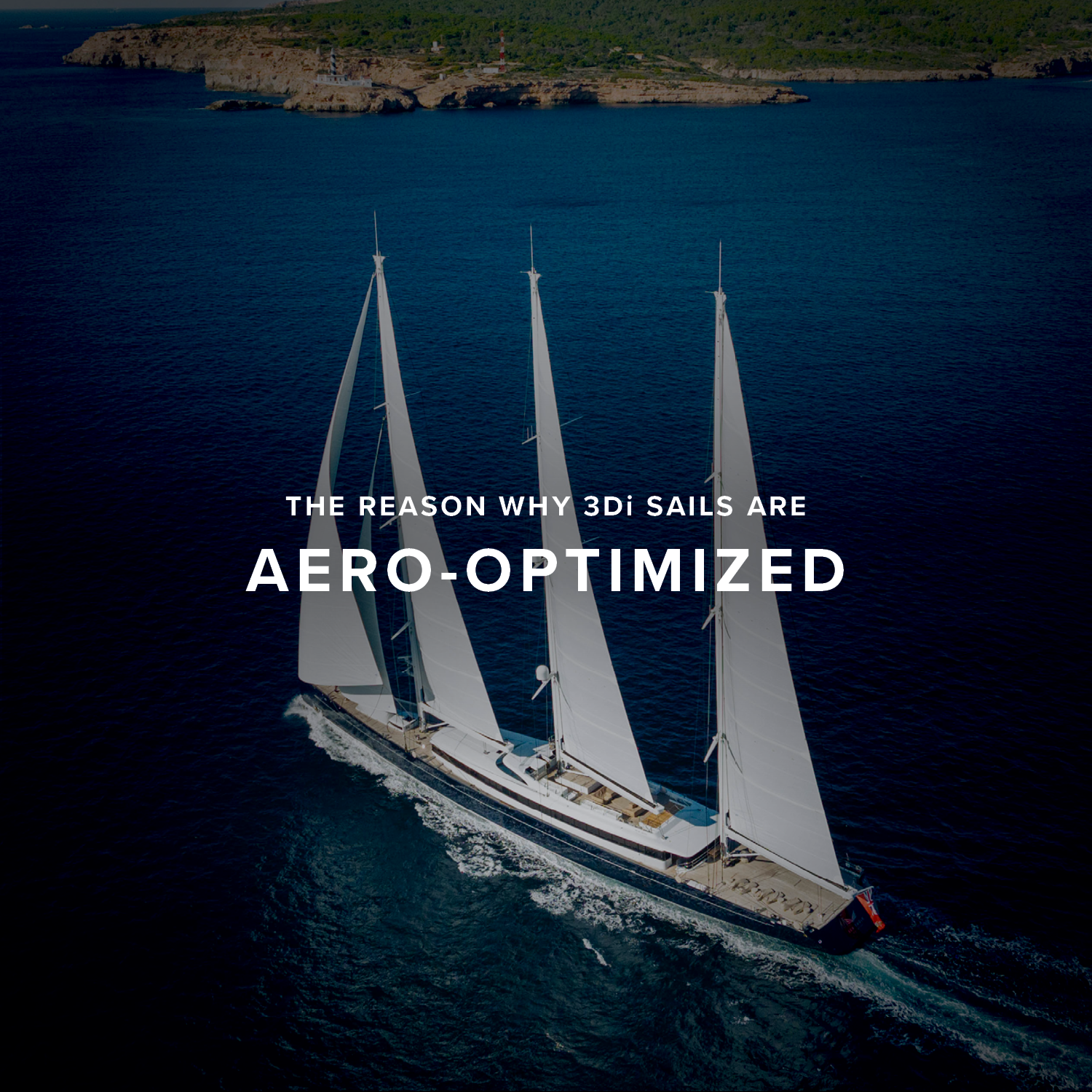

3D SHAPED SAILS

A streamlined sail shape delivers less drag, more drive, and greater effectiveness across a wider wind range.

A streamlined sail shape delivers less drag, more drive, and greater effectiveness across a wider wind range.

A North Sails designer pairs bespoke computer analysis with full-sized 3D molds to precisely match ideal aerodynamic shapes to all types of boats.

The 3Di construction and 3D molding process allow for extreme accuracy in shaping sails, reducing drag and increasing efficiency.

The smooth, one-piece 3Di sails are more durable and resistant to stretching and tears. The effective lifespan of a 3Di sail is considerably longer than the competition.

ALL FILAMENTS, NO FILLER

If another sailmaker tells you they can make a sail lighter than 3Di- that is impossible. With zero Mylar, 3Di sails carry no parasitic weight. Every ounce of a 3Di sail's structure goes towards performance.

If another sailmaker tells you they can make a sail lighter than 3Di- that is impossible. With zero Mylar, 3Di sails carry no parasitic weight. Every ounce of a 3Di sail's structure goes towards performance.

A 3Di sail structure starts with the world's lightest, strongest, most durable filaments, less than the width of a human hair. This is how North designers engineer 3Di sails 20% lighter for equal strength or 20% stronger for equal weight than any competing sail on the market.

The blueprint for 3Di calls for two elements: 3Di spread filament structure and environmentally stable thermoset resin. North 3Di sails contain 70% structural material; 30% resin; and zero Mylar.

Although lightweight, North 3Di sails withstand the rigors of extended use. The sails retain shape and performance characteristics over time, reducing the need for frequent replacement and ultimately lowering overall lifecycle costs.