1977 - NORTH SAILS INTRODUCES DIGITAL SAIL DESIGN

DIGITAL SAIL DESIGN

Lowell North diverged from the traditional, artistic approach to sailmaking by closing his eyes. Lowell listened to the numbers. Historically, sailmaking depended on the eye of the craftsman, who drew from experience and tradition to create beautiful sails in a classic shape and style. From the beginning, Lowell embraced a scientific approach to making sails, and North Sails has followed a path of increased development in sail design and production ever since. Remaining at the forefront of design is possibly the clearest example of how Lowell’s core values enabled his company to prosper well beyond his own tenure.

It started with testing raw material properties. The early North Sails team in San Diego pushed innovation in sailmaking to new heights by contriving devices that would apply measurable wear and tear to cloth samples, eventually introducing controlled environments with wind tunnel testing and model sails. The process took a digital direction in 1977, when North transitioned from shaping broad seams on the floor to generating 2D curves with a computer. Working from North Sails in New Zealand, Tom Schnackenburg based the software on a library of designs selected by group consensus. For a given sail order, a designer would select a curve type from the library, and the software would generate the broad seams for every seam in the sail. The term “consensus” was an important item of discussion at every design meeting, because it would ensure the same sails could be produced at every North loft. At the same time, Tom pioneered 3D design software for sails (insiders call this the “Tin Sail Program,” due to the sail shape being fixed in space), which he used to derive the 2D broad seam curves.

Prior to the arrival of common computers, a designer would run both the 2D and 3D programs on a dial-up service to a main frame. Essentially, they were connecting via a phone line to a computer the size of a hotel room.

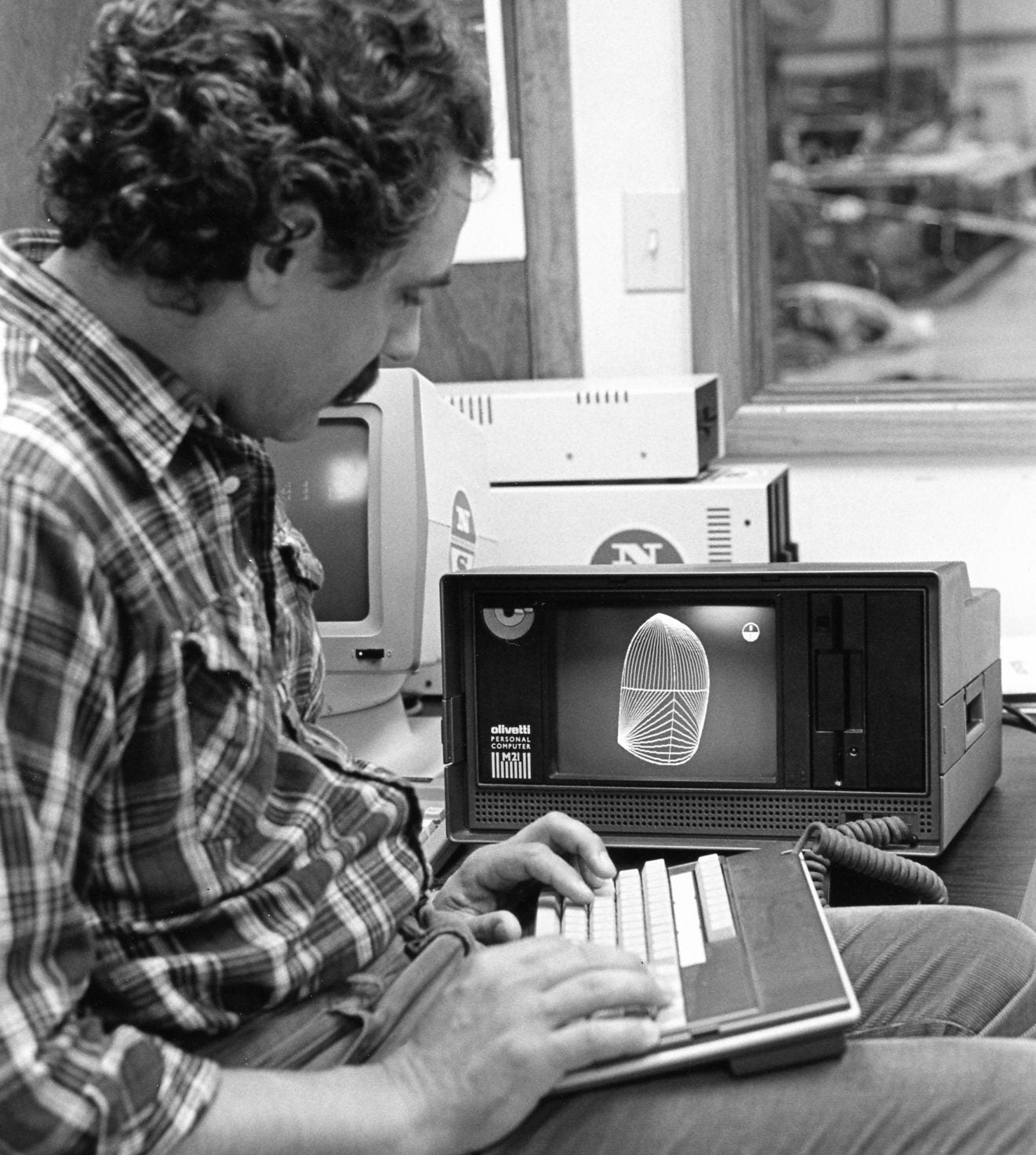

The first in-house computer arrived at the loft in San Diego in 1979. It was a Cromemco, presumably considered the Cadillac of desktop computers if only because of its size. Tom had just opened a loft in Auckland, and a fellow North programmer, Michael Richelsen, brought the computer to New Zealand as checked luggage. Tom started to port his 2D and 3D design software from the main frame to the Cromemco, which was running an early version of Microsoft DOS.

It was in the early 1980s when Michael began focusing on the work that would eventually expand the North Design Software to what it is today. By 1987, Flow™ and Membrain™ made it possible to apply wind pressure to a sail’s surface and calculate the load forces created. Designers could pressurize their shapes virtually to discover what the flying shape would be. This was the beginning of the Virtual Wind Tunnel™, which models air flow on upwind and downwind sails. By the early 1990s, the addition of the VPP (velocity prediction program) would allow designers to further quantify the performance of the flying shape.

Meanwhile, progression in design evolved into computer-driven production, with large plotter tables drawing and cutting panel shapes to the design spec. This required North to collaborate with early plotter table manufacturers such as Lawson; later the team would build their own and install them at central lofts throughout Europe, North America, and Oceania.

1977 was an important year because it put North Sails on the map in the earliest days of digitalization. Steve Jobs finalized the Apple 1 in the same year. The first microprocessor was only introduced by Intel in 1973. The first computer to use the standardized user interfaces of today, such as icons, a mouse and a desktop screen, was introduced by Xerox in 1975.

Today, North Sails Design SuiteTM (NDS) is the most powerful and diverse sail design tool in the industry. A family of 14 specialized software modules, NDS delivers unprecedented power and flexibility to sail design and rig/hull analysis. The modules interface with each other to make it possible for North Sails designers and engineers to virtually test a boat and sails in an infinite variety of conditions before the boat is even built. NDS significantly expands a designer’s ability to compare different sail and rig combinations and accurately measure results.

Thanks to North Sails’ heritage and design experience, we know that our software models accurately replicate how sails perform on the water. For 40 years this analysis, data and insight has been an integrated and crucial tool for clients all over the world, from huge new concept projects through to habitual cruising and racing sailors.

*Group photo: back row from left to right: Paul Davis, Keith Lorenz, Lowell North, Peter Mahr, Dave Hirsch, Albert Schweitzer, Angus Melrose, Larry Herbig, Jay Goebell (second from right). Front row from left to right: Joep Strauss, Mike Schreiber, Steve Reid (behind), Rick Sternkopff (in front), Steve Grover (behind), Michael Richelsen (in front), John Marshall, Monica McCantz, Tom Schnackenberg, Peter Kay, Robert Hopkins, Bill Bergantz.