NORTH SAILS BLOG

All

Events

Guides

News

People

Podcast

Sustainability

Tech & Innovation

Travel & Adventure

news

NORTH SAILS WELCOMES MATTEO SANGIORGI

NORTH SAILS WELCOMES MATTEO SANGIORGI

North Sails expands the global One Design team welcoming Matteo Sangiorgi

Gosport, UK, January 31st 2018: North Sails have announced today that Matteo Sangiorgi has joined North Sails as a One Design Expert for the Optimist Class.

“I decided to join North Sails because I love the idea of being part of a company that is able to supply sails for everyone from Optimist sailors to America’s Cup sailors. I also like the idea of being involved in such a big network, where research and development a key focus for everyone.”

Matteo brings years of experience with him, from coaching Optimist sailors to sail development in the Optimist, 420 and 470 classes. He will work alongside the global One Design team with a focus on the Optimist class to increase our market share in the most popular and largest global junior racing boat.

Tim Healy, President of One Design at North Sails added,

“We are delighted to welcome Matteo to North Sails. He brings a wealth of experience and his passion and dedication for the sport is clear. Combine this with his valuable knowledge and sailing skills makes him a great asset to our one design team.”

North Sails is backed by over 60 years of experience in One Design sail making and design. North’s team of One Design experts utilize design and product innovation available to supply the most advanced sails to One Design fleets, which includes everything from club racers to Olympians.

Full Interview with Matteo

READ MORE

READ MORE

news

DAY DREAMING OF SAILING?

DAY DREAMING OF SAILING?

Escape with North Sails Waterlogs

Landlocked? Cabin fever? Have not seen the sun in days? Many of us in the Northern Hemisphere are counting down the days until winter is over and we’re back on the water.

While we can’t put you on a plane and fly to warmer water, North Sails is serving up daydream-worthy reading through our Waterlogs. Our Waterlogs are a collection of stories from our cruising customers around the world. The stories range from cruising on a multihull in the Mediterranean with 3Di NORDAC to Tom and Susie Partridge who stopped by our loft in Sri Lanka en route to Cape Town, South Africa. Whether you’re a racer or a cruiser, we all appreciate stories about casting off the dock-lines and using the wind to power our journey.

We hope you enjoy reading these stories as much as we like receiving them. Just don’t let your boss catch you daydreaming!

Gustave’s Adventures in the Mediterannean

One couple, three young children, a catamaran, and six months sabbatical to make the most of the Mediterranean. That was the project in 2017 for Jérôme Aubert, 40, and his wife Hélène, 35. Not necessarily an obvious choice for this sailing professional as he has been working at Harken for eight years but the family wanted to leave it all behind them and take off on an adventure. Click the photo for full story.

3Di NORDAC Test Sail

Everyone at North Sails was excited to launch 3Di Nordac in June 2017. We wanted to share the news far and wide and tell all our customer about the new addition to our 3Di product family. In preparing for launch, we sent Bill Fortenberry, our cruising segment leader on a test sail in the BVI’s. The perks of working for North Sails! Click the photo for full story.

Adina Explores Sri Lanka

Tom and Susie Partridge were early contributors to the North Waterlogs. They are from the UK but were making their way from Asia to Cape Town, South Africa. Tom emailed us one day to say they were going to be in Sri Lanka for two weeks and was possible to stop by our factory in Sri Lanka. Naturally, we welcomed him with open arms. Click the photo for full story.

First Hoist With Onne van der Wal

Onne van der Wal is a name you may have heard. He is a world-class photographer who spent the winter of 2016 restoring his Pearson 36. Being a photographer, Onne documented this project and shared his first hoist story with North Sails. Click the photo for full story.

Still want to get away? Read all of our Waterlogs here.

Do you have a story to share? We’d love to hear from you! Email us at contact@mktg.northsails.com.

READ MORE

READ MORE

news

NORTH SAILS BRISBANE JOINS THE NORTH SAILS GROUP

NORTH SAILS BRISBANE JOINS THE NORTH SAILS GROUP

The Local Agent is purchased by North Technology Group

The North Sails Group is pleased to announce that North Sails Brisbane will become the latest loft to join the company. Founded in 1993 as Bradford Prentice, the loft set up by Mark Bradford and Vaughan Prentice has long since established itself as the largest sailmaker in Queensland and since 2001 they have been operating as a local agent of North Sails. Following the 2017 acquisition of North Sails Australia, which included both the Sydney and Melbourne businesses, today’s announcement sees the Brisbane team join the Group as a fully serviced, North Sails loft.

The loft has manufactured, sold, and serviced thousands of sails up and down the Queensland coast. The team pride themselves on their ability to understand their clients needs and find a sail solution that works for any size of boat, from the smallest dinghy through multihulls, right up to the racing super maxis and everything in between. In line with the North Sails Group ethos, the acquisition of the loft is aimed at giving customers an enhanced experience – while still dealing with Mark, Vaughan and the team on the ground they will also benefit from the shared technology and wealth of knowledge from within the Group. The growing global company, well known for its revolutionary North 3Di sails, has a network of lofts unrivaled by any other sailmaker in the world and continues to invest in innovation and technology, which in turn creates the market leading sails clients have come to expect.

Mark Bradford commented:

“Vaughan and I have greatly enjoyed setting up and running what has become North Sails Brisbane but we are hugely excited by this next step to giving our clients an even better service. We want to make sure that anyone that walks into our loft ends up with a sail perfectly suited to their sailing needs and part of that is making sure we are at the cutting edge of new technologies and able to offer the latest and greatest sails possible. We believe by joining the North Sails Group we can do that and all the staff at North Sails Brisbane are hugely looking forward to all that this new stage will bring.”

Ken Read, North Sails Group President commented:

“The core of our whole business is understanding the local culture and sailor by delivering sail solutions that exceeds their expectations. We are delighted that North Sails Brisbane is joining North Sails Group helping us to further develop our network and enhance our global customer experience. As we continue to push the boundaries of technology and put a huge amount of focus into research and development, we are excited to be able to share this with our lofts and customers around the world. I am delighted to welcome Mark, Vaughan and their team to the North Sails Group and look forward to working with them in the coming years.”

READ MORE

READ MORE

news

NORTH SAILS DESIGNS INVENTORY FOR NEW MELGES IC37 CLASS

Designer Mike Marshall explains 3Di sail development

When notified that North Sails would be the official sailmaker for the Melges IC37 class, the design team realized we had a challenging task before us. An inventory of only three sails – one main, one jib, and one spinnaker – and only one standing rigging tuning adjustment allowed during class regattas (the mast ram). Given these requirements, how could we design a set of sails to cover the entire wind range when racing this 37-foot one-design boat? Fortunately, we had all the tools we needed with North’s 3Di technology and the North Design Suite of modeling software.

It was clear from the outset that 3Di was the only option for sails that could take the loads of a 37-foot boat yet perform well in winds anywhere from 5 to 25 knots. With 3Di, tapes are oriented in the direction of the loadings, giving outstanding stretch resistance, and Aramid and Dyneema fibers provide exceptional durability. So the 3Di decision was an easy one.

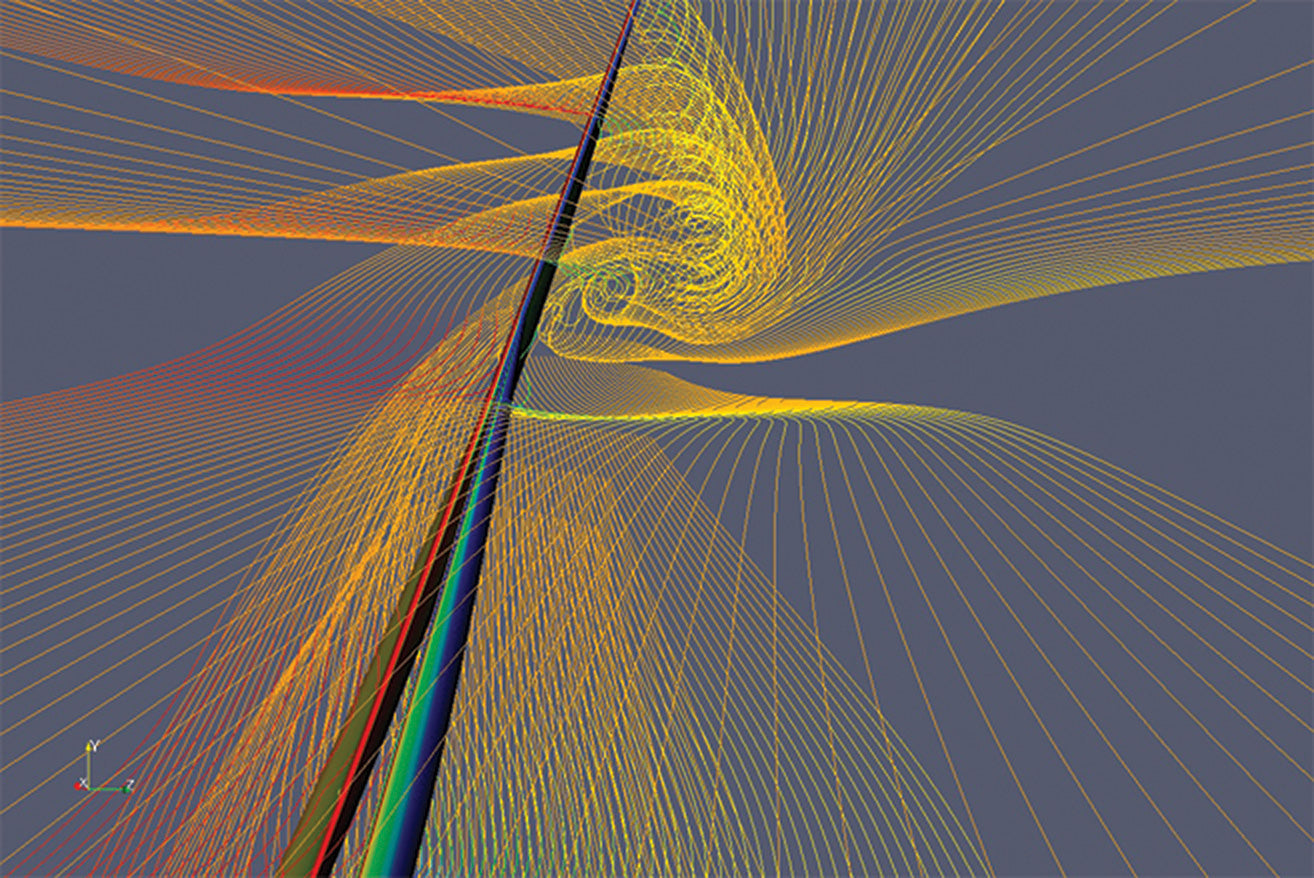

Next we got to work perfecting sail shape through aero-elastic modeling. In a seven-step process passed down from years of America’s Cup development, the Melges IC37 sails were modeled in a variety of wind conditions. Thanks to a close relationship with Southern Spars we had access to very detailed mast information, such as mechanical properties and rigging attachment points, which allowed us to design sails that would perfectly fit the mast of the Melges IC37.

Here are the seven steps in the sail development process:

Step 1: Build a model of the rig. Using North’s Desman program, we created a complete three-dimensional model of the spars and rigging.

Step 2: Determine the base rig tune of the mast. Through our partnership with Southern Spars, we obtained the maximum loaded tuning and rigging specifications for the Melges IC37 and ran it through the program Membrain, to determine the maximum and minimum mast bend from tuning. This, in turn, provided the minimum and maximum mast ram positions and the range of mast bends and headstay sags the sails would see up the wind range. .

Step 3: Design the sails and place them on the rig. Using the program Spiral, we specified a shape for each sail. This software defines a sail’s three-dimensional shape as a “molded” surface without any wind pressure or load applied.

Step 4: Define the structure of the sails. Using the software module Warps, we selected 3Di construction and created the taping layout of the sails. The structure of a sail is as important as its designed shape, because these two factors must work together to achieve the sail’s “flying shape.”

Step 5: (left) Apply wind pressure to the sails and rig. We used the program Flow to introduce wind pressure over each sail’s three-dimensional mold and produce a pressure map on the sail’s surface. This pressure field was then linked to the program Membrain, to see what effects wind pressure would have on the molded sail shape.

Step 6: (right) Apply a pressure map to the molded sail shape. Using Membrain , we took the rig and sail model developed in the first four steps and applied the pressure field from Step 5. Membrain considers the specific properties of the sail’s construction, adds in wind pressure, and shows how the sails will deform (stretch) when they are loaded.

Step 7: Carry out aero-elastic coupling. Once a sail’s flying shape is tuned and trimmed in Membrain, the deformed (pressurized) shape is sent back to Flow. This shape is different than the molded shape created in Spiral (without any wind pressure), so Flow recalculates a pressure map, which is then sent back to Membrain and applied to the sail to get a new deformed shape. This process is called aero-elastic coupling. Within the North Design Suite, the computer keeps going back and forth between Flow and Membrain until there is little or no additional change in Membrain’s deformed sail shape. At this point, we know that the sail shape is in balance with the wind loads on the sail.

After carefully considering multiple design options and running many load cases, we developed a set of sails for the Melges IC37 that would optimally fit the range of mast bends and perform well from 5 knots of breeze all the way up to 25 knots. We also determined the tuning for the mast, all before the first boat even left the mold.

North’s 3Di technology and North Design Suite go hand-in-hand and we are excited to see our work come to life when Hull #1 hits the water in a few weeks. What goes on behind the curtain tends to go unnoticed, but with the new launch on the horizon, our designers are proud to introduce to you the new North-powered Melges IC37 Class, the newest addition to Corinthian one design competition, with industry-leading technology that sailboat owners and crew will love.

Find out more on the Melges IC37, or speak with your local expert today.

READ MORE

READ MORE

news

NORTH SAILS EXCLUSIVE SAIL SUPPLIER FOR THE NEW IC37 BY MELGES

NORTH SAILS EXCLUSIVE SAIL SUPPLIER FOR THE NEW IC37 BY MELGES

North Sails to Deliver the First Set of Sails in Early 2018

North Sails is a proud to be the exclusive sail supplier to the new IC37 by Melges. A fun, modern 37-foot race boat, this exciting new class will make its debut in the spring of 2018. The first 20 hulls have been purchased by the New York Yacht Club for the 2019 Rolex New York Yacht Club Invitational Cup, and it is Melges’ expectation to grow the class to an international audience over time.

North Sails President Ken Read and One Design experts have been working with boat designer Mark Mills and the New York Yacht Club to design an inventory that best supports this Corinthian focused class. North Sails will deliver the first set of sails in early 2018.

“The IC37 by Melges is a perfect example of a class that will be accessible to the masses,” commented Ken Read. “We have designed high performance yet cost controlled inventory that puts focus on smarts and crew work, rather than managing a large sail inventory. The class will enforce a strict one-design rule, limiting expensive sail development arms races. As exclusive supplier to events like the Volvo Ocean Race, America’s Cup, M32 circuit, and Extreme Sailing Series, the choice of North Sails as a supplier ensures IC37 owners will have industry-leading technology.”

Learn more about the IC37 by Melges by visiting MelgesIC37Class.com

READ MORE

READ MORE

news

HOW TO CARE FOR YOUR SAILS THIS WINTER

As we come to the end of the sailing season and head into winter, the North Sails global service team is gearing up for a busy period - from helping clients prepare for the Caribbean season, to packing boats away for a winter hiatus.

READ MORE

READ MORE

news

NORTH SAILS DOUBLES DOWN ON R&D

NORTH SAILS DOUBLES DOWN ON R&D

At North Sails, product development and technological innovation have been core functions for 60 years. As we look toward 2018, the company will further solidify its research and development roots by establishing a formal R&D hub at the loft in Vannes, France. Head-up by French designer, Gautier Sergent, the R&D center will organize the activities and energy that have historically been widespread throughout North Sails.

Most of the significant breakthroughs in sailmaking, from 3D molded sail manufacturing through to today’s 3Di composite foil structures, have been achieved by merging sophisticated computer modeling with creative mechanical engineering and bold ideas hatched on the water. With the Vannes R&D center, North Sails takes a proactive approach to bringing these three pillars of progress together.

Tools of the Trade

Fluid-Structure Interaction, or “FSI” in engineer-speak, is the practice of analyzing the relationship between a structure and its fluid environment, such as a hull passing through water or a sail through the wind. North’s development of bespoke software began in 1977 with the digitalization of 2D curves on the world’s first computers. Over the years it evolved to include a family of modules, notably MemBrain™ and Flow™ in 1987, which couple to apply wind pressure to a sail’s surface, calculate the load forces created and the resulting deformed shapes. Today, North Sails Design Suite™ (NDS) is the most powerful and diverse sail design tool in the industry with 14 modules delivering unprecedented flexibility to sail design and rig/hull analysis. By interfacing with Open Foam software, NDS offers a complete FSI and the ability for North Sails designers to virtually test a boat and sails in an infinite variety of conditions before the boat is even built.

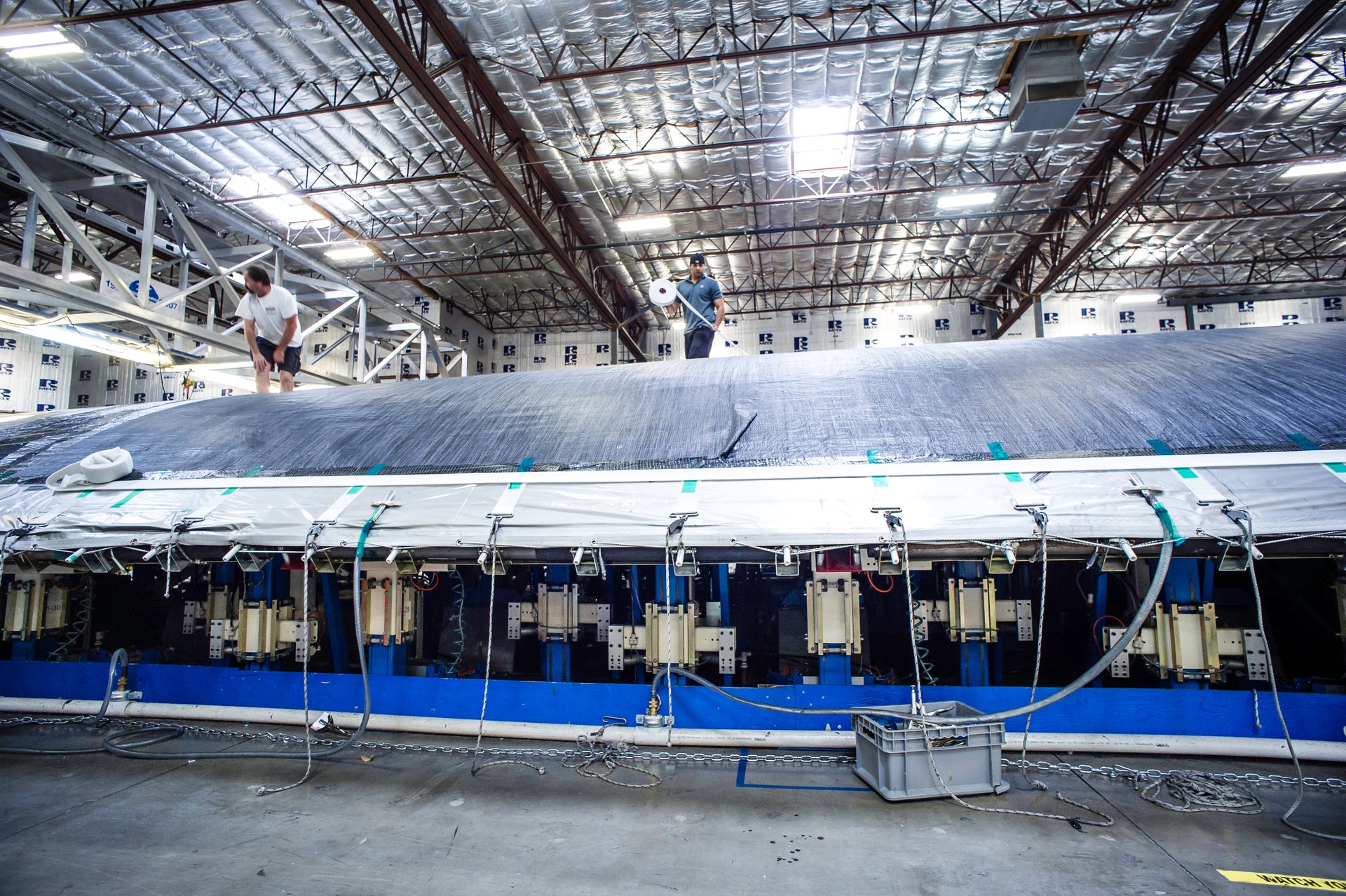

Even Better in 3D

If designers use software to draw a perfect shape, it’s the engineer’s job to build it in real life. North Design Suite is fully integrated with North’s automated 3D manufacturing, providing the designer and the engineer complementary tools to achieve results. Starting with raw materials, the North Sails R&D team is able to design and manufacture a sample completely from scratch within a controlled manufacturing process. This opportunity for in-house development has fueled the patent of new manufacturing technologies and breakthrough products. The 1992 introduction of North Sails 3DL marked the first sails to be built on a three-dimensional mold according to a design load path. North Sails 3Di followed in 2010 to mark the first composite sail ever brought to market. Also built on a 3D mold, North 3Di has set a new standard for shape and structural durability, with clients sailing upwards of 5,000 hours on the same set of sails, while breaking the toughest records on the ocean.

Dreams with Discipline

Our founder, Lowell North, pioneered his own approach to sailmaking by applying a scientific method to the pursuit of his vision. Remaining at the forefront of development is possibly the clearest example of how Lowell’s core values have enabled North Sails to prosper well beyond his own tenure. No idea is rejected for being too difficult. All development is carried out with the discipline of scientific method.

It takes confidence to dream, and expertise to make dreams reality. By anchoring North Sails R&D in Vannes, the team joins a community that has consistently pushed the boundaries of our sport harder, and earlier, than anywhere in the world. North’s track record of disrupting the industry with new technology matches the ambition of the world’s top sailors, many of them based in France.

As the new leader of North Sails R&D, Gautier Sergent brings a wealth of experience and fresh energy to the department. A French native, Gautier started out as an apprentice designing for a senior team at North Sails in New Zealand – another highly innovative sailing pole – after which he took on a sequence of major design projects for the company. Gautier is the Volvo Ocean Race sail designer of record for the VO65, including the 2014-15 and 2017-18 race inventories, and designs for a handful of high profile clients currently making history on the water; Thomas Coville, Francois Gabart, Jean-Pierre Dick to name a few. As Thomas broke the Transat Jacques Vabre course record this week, Francois broke his own standing 24hr solo distance record on Tuesday, November 14th. At the moment the young Francois is sailing well beyond the pace needed to surpass Thomas’ circumnavigation benchmark, on a boat that dates our wildest dreams by a year or two.

After breaking the singlehanded circumnavigation record last Christmas, Thomas Coville thanked North Sails.

“I want to thank North Sails for trusting in me. It’s easy to find people to trust you after the idea works, but North Sails was with me from the start. And that is why I am here today. With our project, with our dreams, you prove there is nothing and no one who can stop you if you have a dream.”

In the past three years, Gautier relocated to Minden, NV in the United States to manage the company’s 3Di production hub. The 3D factories are special places where material science, mechanical engineering and machine build are all handled completely in-house. Three years of working in close proximity with North’s inventive staff has given Gautier a solid foundation in our capabilities, the potential of our materials and the R&D process that has proven successful. Along with his background in sail design, this experience combines well with a personal passion for cultivating ideas and leading a team to pursue the impossible.

READ MORE

READ MORE

news

NORTH SAILS GROUP SELECTS VANNES FOR ITS GLOBAL R&D HUB

North Sails Group selects Vannes for Global R&D Hub

Boat Industry interviews North Sails head of R&D, Gautier Sergent on his ambitions for the department

2018 will see North Sails found a center for Research and Development out of Vannes (France). Experienced designer and department head, Gautier Sergent, explains to BoatIndustry their objectives and philosophy, which have the potential to go beyond sails.

You are going to take charge of the North Sails R&D center in Vannes. Could you tell us how you got here?

Gautier Sergent: After completing my studies in engineering in France, I joined North Sails in New Zealand in 1999 for a final internship. At the dawn of the America’s Cup in 2000, the teams were very busy out there and so I was able to help, which got my foot in the door. I was hired by the sail loft whilst also undertaking a Masters at Auckland University in the Yacht Research Unit at the same time. I then worked on the development of the software for CFD (Computational Fluid Dynamics), and then I became a designer.

In 2010, I returned to France to work on the Groupama project in the Volvo Ocean Race. I spent time with members of the crew who also each had their own teams, such as Thomas Coville. We built up some great relationships and I stayed in France to work on a number of IMOCA and Ultime projects.

In 2014, I became head of the 3D factories for the North Sails group in Minden (USA) and Sri Lanka. At the end of three years, which we had agreed would be the minimum required for such a post, we determined with management that my profile and expectations corresponded to the new project to develop R&D within the group. From October 1st 2017, I will therefore take charge of the new R&D center.

How has R&D at North Sails worked up until now and what were the reasons behind creating this R&D center?

GS: Of course R&D existed before this initiative. It is even part of the DNA of North Sails, but up until now it was spread within all the different entities of the group. It was never the priority of one person in charge, which could slow down the process. Moreover, it was never considered for all the markets and the information was scattered.

From now on, I will be in charge of structuring and coordinating the R&D efforts for North Sails around the world. Thanks to the R&D center, we will be able to streamline and ensure the research efforts are as efficient as possible. As a first step, I want to establish an inventory and back catalogue of North Sails R&D. From there, we will be able to establish a 5 year plan of attack and forecast the budgetary and personnel requirements. The objective in the long term will be to hire 3-4 people.

What are the main areas of R&D that you are exploring?

GS: Even if the subjects are refined after the inventory, several research topics are already envisaged. There will obviously be development for CFD software. We will also work to simplify and integrate as much as possible, or even completely remove the some finishing aspects of sails, such as straps. We are going to study the integration of the mast and sail with Southern Spars which, together with North Sails, is part of the North Technology Group. Electronics and the gathering of data is an area we’d like to streamline in order to better understand the dynamic behavior of sails, and apply this knowledge to physical test protocols and laboratory simulation for sails.

We will also focus on product development and continue to expand 3Di to cover all types of sailing. With this year’s introduction of 3Di NORDAC, we have made a huge step by using a new material: Dacron. With this result we will work to see the possibilities of marrying up polyester fibers with Aramid, Dyneema or Carbon, to draw out the best characteristics from each one.

Why did North Sails choose France to install its R&D center?

GS: The French sailing market is one of the least cautious. The projects that one can find between Lorient, Port-La-Forêt and la Trinité are exciting and the French are not afraid to invest in technology.

On the other hand, with the tax credit, it is possible to reduce personnel costs to the level of other countries. Among the hires at the R&D center, there will certainly be someone in charge of partnership management with universities, companies and grants.

This interview was originally published by BoatInsider.com

© Amory Ross/ North Sails

© Ian Roman / North Sails

© Ainhoa Sanchez/Volvo Ocean Race

READ MORE

READ MORE

news

3Di FORCE FEATURED IN SEAHORSE TECHNICAL REVIEW

Fast Boats Just Got Faster

The 3Di Force Code 0 built for Volvo winner Groupama is now available for all

© Pedro Martinez / Volvo Ocean Race | Mapfre leads this year’s seven-boat Volvo Ocean Race fleet across the startline in Alicante. An increasingly popular application of 3Di Force can be seen here in the one design A3 in this year’s VO65 sail inventory.

Building on its success with 3Di across grand prix, offshore and superyacht fleets, North Sails has launched a new variant tailored specifically for downwind applications. For the Volvo Ocean Race 2011-12 sail limits on the outrageous VO70s were tightened down following the previous event from 24 to 17 sails for the whole race. North’s immediate focus was to try to figure out if any sails could be removed from the previous inventory without negatively affecting performance over the length of the course. 3Di was a new technology back then, and the bet was taken by both North Sails and some of the teams that it would perform better, and for more hours than string sails, therefore allowing fewer sails to be carried onboard.

Gautier Sergent, lead sail designer, had felt that in heavy-air downwind crews tended to back off to avoid breaking the boat – and the sailors. So if there was a sail that could be removed from the replacement cycle through less wear and tear, it might be the heavy-air downwind fractional Code 0 – as long as weight did not have to be added to make it bulletproof. Hence it was decided to develop a new fractional Code 0 that could last the whole race, while being light, fast and stable enough to reach at higher angles than the previous sail; the 3Di Force concept was born. This sail type not only went around the world on Groupama without any problems, it ended up becoming quite famous… as the team approached Lorient on the race’s epic penultimate leg.

With the wind blowing 48-50kt, it was time to gybe for the finish. The Groupamacrew decided to gybe with everything up, focusing their attention on the mainsail to ensure they did not break all their battens… or drop the mast. So the fractional Code 0 would have to survive this manoeuvre while being attended to last, left to flog in the howling conditions before being sheeted back in. The crew pulled it off, the sail survived. And they went on to win the leg and the race.

Skipper Franck Cammas later reported to Sergent that they had faith in their 3Di Force and were not unduly worried about breaking the sail – being more concerned about dropping the mast…

Similar on the outside… inside it’s a whole different story

The 3Di layout spreads filament pre-peg tapes in a multiplicity of orientations which enables a downwind sail to be engineered with high precision, and without the weight of the film required for a Mylar-based string sail. 3Di manufacture is also a vertically integrated process, North Sails controlling everything down to the tape manufacture. This allows the company to tailor materials for applications and opens up an infinite number of fibre combinations in terms of type, dpi and adhesive content/type.

This is what allows Force to be completely different from 3Di Raw. 3Di Force was designed from the outset for downwind applications, so loadings are quite different from the upwind case and more biased towards the luff than the leech. The AWS is typically much lower downwind and the sails much larger than upwind sails, so the weight becomes a greater factor in ensuring the sail flies correctly.

The loading is also more dynamic because of the broader angles and faster AWA changes as the boat accelerates/slows. This requires a high strength-to-weight ratio: the ability for a sail to sustain high loads for a given weight.

The sails are deeper than upwind sails as well, so the weight-tomodulus ratio (the ability of a sail to resist stretch for a given weight) can be slightly moderated. In fibre terms this typically means significantly more Dyneema than would be used in an upwind sail.

Combining those two factors – a luff-loaded structure and high Dyneema content – is a great solution for a light but durable downwind sail, while retaining the flying stability of 3Di. 3Di Force employs North’s proprietary 3D moulding technology with its precise control over shape, combined with the high-resolution

3Di tape structure. The end result is 3Di Force being capable of creating super-light sails with exceptional shape stability.

Why did it take North so long to release 3Di Force to the general market? Mainly because its application was limited due to the minimum weight of a 3Di sail at the time. Later, in 2013, North invented 3Di Raw, which reduced the minimum achievable weight without compromising the sail structure. Today 3Di Force has become the benchmark for downwind sails on fast boats. It is light, strong, very precisely shaped and more stable than other technologies. Sailors commonly highlight improvements in acceleration detected with sails built in 3Di Force; a big reason for this responsive performance is that the unmatched stability of these sails means better use of gusts, translating the extra power into speed. It also shares the attribute of every 3Di sail and increases the sweet spot/effective wind range of the sail, thereby reducing the number of sails needed.

From Imoca 60s to Ultimes, boats are doing away with paneled downwind sails completely. The 3Di Force fractional Code 0 is also a great addition to the armory when reaching with AWA ranging from as close as 45° upwards…

This story was originally published in Seahorse Magazine Technical Review, December 2017.

© Jen Edney/Volvo Ocean Race

READ MORE

READ MORE

news

NORTH U HOSTS INAUGURAL OPTIMIST CLINIC IN MIAMI, FL

NORTH U LEADING EDGE OPTIMIST CLINIC PRESENTED BY NORTH SAILS

Advanced Opti clinic with top North Sails Optimist Coaches and Experts in Miami, FL

North U is hosting the Leading Edge Optimist Clinic on November 2nd and 3rd in conjunction with the Southeast Champs, Nov. 4-5th. Hosted by Key Biscayne Yacht Club in Miami Florida, the clinic will include on the water sail testing sessions with the North Sails Optimist product line test sails, where sailors will be equipped with GPS tracking. Sail set-up and advanced tuning techniques will be discussed, paired with seminars on ‘How Sails Work’ led by Optimist Experts Zeke Horowitz and Mike Marshall. Awards will be handed out on Friday to the top performing sailors at the clinic. Charter boats are provided by McLaughlin Boatworks. Join us in Miami on Nov. 2-3rd for an interactive sailing experience with one of the best Optimist coaches in the nation.

“I am really excited about our first ‘Leading Edge’ High Performance Clinic presented by North Sails. At this clinic we would provide all the sailors with top information on how to improve their techniques and have a better understanding on how sails work!” -Juan Carlos Romero

Looking for a boat to charter?

Registration is OPEN. Click here to sign up today!

Clinic Schedule:

THURSDAY, NOV. 2nd

8:30 am – Check-In / Breakfast Buffet & Make Your Lunch

9:00 am – All sailors rigged & ready

9:00-10:00 am – Sail Set-Up & Rigging Tips

11:30 – 4:00 pm – On-the-Water Training & Sail Testing

4:00 – 4:45 pm – Debrief / GPS Tracking Analysis

5:00 – 6:00 pm – ‘How Sails Work’ Seminar with North Sails Experts Mike & Zeke

FRIDAY, NOV. 3rd

8:30 am- Breakfast Buffet & Make Your Lunch

9:00 am -All sailors rigged & ready

9:00 – 10:00 am – ‘How Sails Work’ Seminar with North Sails Experts Mike & Zeke

10:30 – 4:00 pm – On-the-Water Training & Sail Testing

4:00 – 5:00 pm – Debrief/ GPS Tracking Analysis

Coaches: Who are they?

Juan Carlos Romero is one of the most accomplished and experienced coaches in the Optimist class with nearly 25 years coaching experience. Born in Ecuador, Juan has coached at many top programs such as the Annapolis Yacht Club, St. Petersburg Yacht Club, Lauderdale Yacht Club, Coral Reef Yacht Club and is currently the Sailing Director at the Key Biscayne Yacht Club in Florida. Juan has also coached the Ecuadorian and United States National Teams in international events such as South Americans, North Americans and Worlds.

Zeke Horowitz grew up in Sarasota, Fla. where he quickly took to sailing and began racing in the Optimist Class at the age of nine. His Optimist racing took him all over the world and inspired his passion for sailing and the camaraderie that comes with the sport. He continued on to race in other dinghies and small keel boats throughout high school, garnering multiple state and national championships along the way. Zeke attended The College of Charleston in South Carolina where he was selected as an Honorable Mention All-American twice, as well as an Academic All-Conference All-American. Zeke was team captain his senior year, and led the Cougars to their first ever ICSA Team Racing National Championship.

Mike Marshall grew up in Rhode Island racing Optimists, 420s, and Lasers. He graduated with a degree in Geophysics from Connecticut College, where he was co-captain of the sailing team for two years. He is currently focusing on designing sails for one-design boats and one-design custom projects, including designs for the US Olympic 470 teams and many other world-championship-level programs.

For additional information, contact:

North Sails Head Coach Juan Carlos Romero at 410-212-5303, juancarlos.romero@northsails.com

READ MORE

READ MORE

news

J24 IRISH NATIONAL CHAMPIONSHIP 2017

North Sails powered boats take all the podium positions in this years 2017 National Championships, with 12 out of the top 15 spots also occupied by North Sails customers.

READ MORE

READ MORE

news

WHIDDEN HONORED WITH NATIONAL SAILING HALL OF FAME AWARD

WHIDDEN HONORED WITH NATIONAL SAILING HALL OF FAME AWARD

North Technology Group President Tom Whidden joins eight selected individuals in U.S. National Sailing Hall of Fame’s “Class of 2017”

North Sails would like to congratulate North Technology Group President, Tom Whidden, on his induction to the U.S. National Sailing Hall of Fame. Among many accomplishments throughout a lifelong career in the sport, Tom has remained a lover of sailing since purchasing his first boat, a Blue Jay, at age ten. Tom is among eight individuals selected this year by the National Sailing Hall of Fame, to join a total of 57 honorees inducted since 2011. The “Class of 2017” was congratulated yesterday in an induction ceremony at New York Yacht Club’s Harbor Court, following a weekend of celebratory events.

“I loved the ability to go out and make decisions on your own. I loved the forces around you: the water, the air, the wind and the currents.”

Tom’s reflection of early days on the water indicate leadership qualities, a passion that would see him through eight America’s Cup campaigns including that memorable race in 1983, when Australia II edged victory over the Americans to win the Cup for Australia. Of course Tom, alongside Dennis Conner and the Stars and Stripes crew, bounced back with a vengeance in 1987 to reclaim the America’s Cup in one of the most notable events of Cup history.

To introduce Tom in yesterday’s induction ceremony, Malin Burnham spoke of this memorable time. “Tom was much more than a tactician. First of all he was unofficially, but officially in my mind, the crew chief and crew boss for Dennis. He kept things calm and cool under great pressure… In my mind Tom was Dennis’ equal partner in the 1987 Cup, and many other victories.” A good friend of Tom’s, Malin was involved in the Stars and Stripes ’87 campaign and also boasts two World Championship wins in the Star, one alongside North Sails founder, Lowell North.

In business off the water, Tom joined North Sails in 1986 and ten years later was named President and CEO of North Technology Group. In his 30 years with North Sails, Tom led the company through complex developments and investment in manufacturing technology, with the introduction of North Sails 3DLTM and 3DiTM, and the structure of the organization, shifting from a multifaceted family of locally run companies to a wholly-owned global brand and market leader.

Tom credited his sailing experience for success found in the boardroom, in his acceptance speech yesterday. “A friend of mine once said, ‘We all believe that what we see on the water will help us with what we see on land,’ which is something that has really come true in my life. As I’ve said many times, the parallels between successful business and successful sailing are striking and something I really trade on, quite frankly.”

Tom thanked his family, friends and partners for their support and collaboration by addressing the room and requesting their help increasing access to the sport.

“Each and every one of us needs to take someone sailing.”

Tom Whidden joins company leaders in recalling North Sails’ long history with the America’s Cup and its influence on the wider sport of sailing. Dive into the rich history of North Sails with our series 60 Years of Sailmaking.

READ MORE

READ MORE

news

3Di NORDAC WINS "BEST NEW PRODUCT" AT NEWPORT INTERNATIONAL BOAT SHOW

North Sails 3Di NORDAC Recognized as Game Changing Cruising Sail Technology

*Editors note: North Sails updated the name of 3Di NORDAC to 3Di OCEAN in 2020. It's the same great product, but not with an expanded range. Click here to learn more about 3Di OCEAN.

North Sails 3Di NORDAC was named Best New Product at the Newport International Boat Show awards on September 15th. Introduced in Spring of 2017, 3Di NORDAC transforms polyester fiber into seamless, one-piece sails that are uniquely strong, beautiful, and long-lasting. Presented in partnership with Cruising World, Sailing World, and Yachting magazines, the Newport for New Products panel described 3Di NORDAC as a game-changer for cruising sailors.

“We think this is going to give any cruising or recreational sailboat owner a much better sailing experience, regardless of how they are using the boat.”

Sally Helme, Group Publisher for Cruising World and Sailing World, presented the award on behalf of Newport for New Products. “Transforming polyester fiber into seamless, one piece-sails that are stronger and lighter weight than the woven sails that have been the standard for over 60 years, this new technology gives cruisers a higher performance sail with a better shape and greater shape longevity.”

“It’s an honor to receive this recognition for a product that our development team worked very hard to create. 3Di NORDAC represents a new breed of Dacron cruising sails that provide a better sailing experience for North Sails clients.” said North Sails CEO, Dan Neri.

Designed for the small to medium size cruising boat, 3Di NORDAC addresses an inherent problem of woven polyester sailcloth – it fails to provide true value to cruising sailors because the sails lose their shape long before structural integrity is compromised. By marrying patented 3Di shape holding technology with the toughness and affordability of traditional white polyester, 3Di NORDAC offers cruising sailors a superior sail at an achievable price.

“The sails are more responsive and hold their shape better than traditional panel sails, which allows more control of your sail power and increases your ability to balance the boat,” said Bill Fortenberry, North Sails Cruising Segment Manager. “Moving fast and efficiently through the water is the hallmark of the North Sails cruising experience.”

To learn more about 3Di NORDAC, visit the North Sails booth at the Newport Boat Show on facedock (next to J/Boats), browse product features and benefits on northsails.com, or contact your local North Sails Expert.

READ MORE

READ MORE

news

THE NEW R5 OPTIMIST MAINSAIL

THE NEW R5 OPTIMIST MAINSAIL

North Sails is Proud to Introduce a New Member of the Optimist Radial Series

Designed by the North Sails dinghy experts in Japan, the R5 is the perfect addition to North’s “R Series” Radial Optimist sails. The R Series was designed to deliver unparalleled pointing and acceleration capabilities throughout a wide range of conditions. A radial sail is more “rigid” than a conventional cross-cut sail. The sail holds its shape and responds more sensitively to trimming and tuning changes. This is the perfect Optimist sail for racers looking to get the absolute most speed and versatility on the race course.

Shop R Series | Contact Opti Expert

READ MORE

READ MORE

news

…Y ÉXITO DE NUESTROS CLIENTES

Los ganadores de nueve de las diez clases participantes eligieron velas North Sails para competir en la prueba reina del calendario del Mediterráneo, que durante seis días de competición reunió en la bahía de Palma a una flota récord de 138 barcos de 24 nacionalidades.

READ MORE

READ MORE

news

NORTH SAILS RELEASES NEW 3Di HEADSAIL FOR THE J/105 CLASS

NORTH SAILS RELEASES NEW 3Di HEADSAIL FOR THE J/105 CLASS

The New Li-5 3Di Jib Is Optimized for Under 12 knots

August 3, 2017 (Newport, RI): North Sails released its latest headsail design for the competitive J/105 class. The Li-5 3Di jib replaces the L-4 3DL jib bringing the ultimate consistency and performance of North’s exclusive 3Di technology to this light-air optimized headsail. The Li-5 is the perfect complement for the Mi-4 3Di jib which is an all-purpose sail.

“The North Li-5 3Di jib is great! We left the other J/105’s in the dust and beat a very well sailed J/120 in light air, which we have never done before!” said Mark Lindquist on Sterling.

The 3Di material is a more flexible material and therefore offers an enhanced sail shape in light air conditions having a much more rounded foot. A forgiving luff curve makes it easier to read the wind, helping the trimmer and skipper. The added durability of the 3Di products is also a plus for the J/105 jib. The Li-5 3Di Jib is recommended for winds up to 12 knots.

Consistency is a key feature of 3Di manufacturing. The technology’s reputation has earned North Sails exclusive supplier agreements to the 35th America’s Cup, Volvo Ocean Race and Extreme Sailing Series, all of which mandate identical sails under a strict one-design rule. Featuring a high level of repeatability and quality assurance, North Sails 3Di will benefit one-design sailors in the form of consistent weight, measurements and sail shape.

The new 3Di J/105 light air jib is now available for purchase. To learn more, get in touch with a J/105 Class Expert, or visit our J/105 product page.

READ MORE

READ MORE

news

NEW J-6 HEADSAIL BUILDS ON CONSISTENT RESULTS WITH NEW FEATURES AND BENEFITS

NORTH SAILS ADVANCES WINNING J/70 HEADSAIL DESIGN

New J-6 Headsail Builds on Consistent Results with New Features and Benefits

July 25, 2017 (Newport, RI): North Sails released its latest headsail design for the competitive J/70 class today. Based on North’s popular J-2 design, the J-6 headsail brings new benefits to sailors seeking an all-purpose option that excels in maximum in-hauling conditions.

Since day one, North has remained at the forefront of sail development in the J/70. Development efforts originated with an out-of-the-box solution released alongside the launch of hull #1 in 2012. Powered by North Design Suite software, the one design sail package was designed in tandem with the J/70 hull and rig.

“The J/70 is an important class for North Sails, we’ve enjoyed watching the class take off in the States, and expand to sailing communities abroad these last few years,” said Tim Healy, World Champion J/70 skipper and President of North Sails One Design. “Our team continues to unlock performance with new sail shapes, and we are excited to offer the J-6 as our latest development for J/70 sailors.”

The J-6 headsail offers familiar sail shape with a few key performance enhancements. A shortened leech creates a higher clew position for more aggressive windward sheeting over the cabin house. The sail also features a slightly deeper entry and a straighter exit down low, allowing a more forgiving steering groove and opportunity for tighter sheeting angles. Based on North’s trademark J-2 J/70 headsail, which clients used to win the 2014, 2015 and 2016 World Championships, the J-6 takes proven performance to the next level by offering a fresh solution to sailors upping their game this season.

“We are very pleased with the new J-6 headsail from North Sails,” said Brian Keane, owner-driver of J/70 Savasana who tested the J-6 during a local event in June. “We believe it is highly versatile, balanced, and allows for aggressive weather sheeting.”

Contact a North Sails expert today to learn more about the North Sails J/70 inventory.

Brian Keane’s Savasana racing with the new J-6 from North Sails, to win the NYYC One Design Regatta in June.

READ MORE

READ MORE

news

J CLASS BATTLE FOR THE KOHLER CUP POINTS IN BERMUDA

The second installation of the Kohler Cup presented by North Sails will take place when the 35th America’s Cup hosts the J Class Regatta June 16, 19-20 in Bermuda. The Kohler Cup is a season long cumulative point championship. Throughout 2017, each yacht will accumulate points based on their results, with events bearing more significance in the lead up to the class Worlds in Newport, RI, August 21-26, 2017. Bermuda will see 2017’s largest fleet and the overall J Class Regatta winner will add 12 points to their series tally.

Jim and Kristy Clark’s JK6 Hanuman leads the Kohler Cup series, collecting six points in St Barth’s. JK7 Velsheda and JK1 Lionheart round out the leaderboard with four and five points respectively. America’s Cup veteran and North Technology Group CEO Tom Whidden joins JS1 Svea in her regatta debut and will be looking to capitalize on the bonus points for winning in Bermuda.

Although the J Class is considered a Superyacht, a betting man (and J Class crews!) will tell you the gloves are off and these boats will be sailed more like small dinghies. Just as modern innovation has delivered the foiling America’s Cup Class, today’s generation of J Class yachts are more responsive and have better boat handling, allowing skipper and crews to race with more confidence. Close racing, close calls and a few choice words are sure to be heard on the racecourse.

Introduced during the 2017 St Barth’s Bucket, the Kohler Cup is named in memory of Terry Kohler, former owner of North Sails, who passed away in September 2016. North Sails is proud to be an Official Partner to the J Class Association and the presenting sponsor of the Kohler Cup.

Join @North_Sails on Instagram Stories for live updates from the J Class Regatta in Bermuda.

J Class run downwind at the America’s Cup Superyacht Regatta in Bermuda.

Ranger, a replica of the original “Super J” that successfully defended the cup from Endeavor II, chases the 1935 design, J-Class Topaz, launched in 2015.

The crew handle sails on the deck of Hanuman, a replica of the biggest J-Class ever built to date: Thomas Sopwith’s 1936 J Class, Endeavour II.

Terry Kohler, owner of North Sails from 1984 – 2014, worked to maintain and reinforce the company’s position as the technological leader in sailmaking.

READ MORE

READ MORE

news

NORTH SAILS 3Di™ TECHNOLOGY DEBUTS IN SMALL BOAT ONE DESIGN

NORTH SAILS 3Di™ TECHNOLOGY DEBUTS IN SMALL BOAT ONE DESIGN

North Sails offers 3Di RACE as standard inventory for the Melges 20

Newport, RI (June 6th, 2017) – North Sails is proud to introduce 3Di sailmaking technology to the Melges 20 class. In the past five years, North Sails 3Di™ has received unrivaled success in grand prix markets, with around-the-world speed records and exclusive supplier status to sailing’s premier events. Adding 3Di as a standard offering to the Melges 20 class is an example of North’s commitment to providing all sailors with advanced sails for an improved on-the-water experience.

North Sails 3Di technology enables sails to be made from fiber and adhesive only—without the need for Mylar film used in string-sails. An automated tape laying system allows designers precise control over the placement and orientation of material within each sail. “For the Melges 20 we have focused on a bespoke tape layout using North Sails 3Di RACE; Aramid/Dyneema sails developed to meet the demands of smaller boats,” said Tim Healy, President of North Sails One Design. “The result is a sail with a wider wind range, a more supple feel and a more user-friendly experience. The ability to adapt this technology for one-design classes makes our team unique and we look forward making 3Di available to more classes in 2018.”

The new Melges 20 3Di mainsail posted its first victory when Mascalzone Latino Jr. claimed the 2017 Melges 20 Scarlino Championships in May. “I was extremely happy with the 3Di RACE sail,” said Cameron Appleton, North Sails Melges 20 class leader and Mascalzone Latino Jr. tactician. “We noticed the mainsail handled a wide range of wind pressure and resulting rig tune. It was a relatively seamless transfer from our 3DL main, the sail reacted on-par with what we’d expect from 3Di RACE vs. 3DL sails.”

Consistency is a key feature of 3Di manufacturing. The technology’s reputation has earned North Sails exclusive supplier agreements to the 35th America’s Cup, Volvo Ocean Race and Extreme Sailing Series, all of which mandate identical sails under a strict one-design rule. Featuring a high level of repeatability and quality assurance, North Sails 3Di will benefit one-design sailors in the form of consistent weight, measurements and sail shape.

The new 3Di Melges 20 inventory is now available for purchase, click here to learn more or get in touch with a Class Expert.

READ MORE

READ MORE

news

A FIRST-HAND REVIEW OF 3Di NORDAC

A FIRST-HAND REVIEW OF 3Di NORDAC

Sail deliveries, fittings, and sea trials with North Sails expert Bill Fortenberry

Being a part of the 3Di NORDAC product development team, I was excited to spend some time this winter sailing in the Caribbean with our final version sails. The project is two years in development, involving a bunch of great people working through some interesting problems, all with a goal of redefining the Dacron cruising sail. An added bonus was including my family over a long birthday weekend! It promised to be a fun trip both personally and professionally.

Descending into the BVI for 3Di NORDAC product testing.

On the plane heading down to BVI, I kept asking myself, “How we are going to extend the trust we have in this product to our customers?” Internally, we know the 3Di success stories well – around the world race durability, record-setting performance and the product’s hard earned approval in the highly demanding Superyacht arena. We trust 3Di and we also trust the science. Polyester is a nearly perfect fiber for cruising sails and, as predicted, applying modern manufacturing technology has resulted in a stronger sail with more permanent shape. Still, gaining the trust of skeptical cruising sailors, who may well be satisfied with cross-cut sails of woven polyester, was on my mind.

3Di NORDAC sails are made with the same precision manufacturing as 3Di Superyacht sails.

This trip had some logistical challenges. The idea was to put our final versions to the test in Caribbean climate. Further, we wanted them on charter boats where we know sails get regularly abused. The plan was eight sails, installed on four boats, all on different islands. As a lifelong sailmaker, the anxiety of delivering sails and running into problems, such as sails not fitting or not arriving when and where we expected, has never left me. The number of sails, the importance of the project and the normal challenges of operating in tropical islands hightened my normal nervousness. Thankfully, a few days later, I was relieved to sit back with a rum drink knowing all of the sails fit and functioned properly – it was now time to go sailing.

A lot of my concerns about building trust were relieved during the sail fitting process. When it comes to understanding quality, first-hand experience is invaluable. While removing the charter sails and installing the 3Di NORDAC sails, I was reminded how heavy Dacron sails can be and how challenging it can be for one or two people to handle them. We have engineered 3Di NORDAC to weigh the same as comparable woven sails, so there was no real difference in picking up, moving flaking or folding the sails. However, the word “bulletproof” came to mind. No one will confuse 3Di NORDAC as a racing sail. Their inherent toughness, along with the familiar look and feel of Dacron will be reassuring to cruising sailors who are concerned with durability.

High quality finishing details are standard features on all North cruising sails.

While the sails do have the basic look and feel of Dacron, there are some important distinctions. First, there are no seams. Composite sails built on full-size 3D molds are truly stunning to see and use. Perfect sail shape that persists in a range of wind conditions is a hallmark of 3Di sails. I kept thinking: we will no longer have to answer the most popular question from cruising sailors at boat shows, “How many rows of stitching do you use?” Answer: none.

Another distinction of 3Di NORDAC is the integration of features like batten pockets and reef points within the sail, reducing the amount of patching and sewn-on parts. The extra strength is applied exactly where it is needed, with the right amount in exactly the right orientation. The sails are stronger as a result.

Once sailing, I was reminded how reefed sail shape is another key distinction of 3D molded composite sails. The reef positions on mainsails and headsails have the reefing structure internal to the sail and aligned perfectly with the sail loads. Reefing most sails is a compromise in performance. Sailing with reefed 3D sails is a welcomed pleasure.

3Di NORDAC offers perfect reefed mainsail shape.

Beyond the differences in sail construction is the difference in performance. It takes fewer adjustments to control the sail power of molded sails. They react as you expect and part of the fun is actively being engaged in sailing the boat to its potential. Rather than sitting back and enduring the ride, the cruising experience is way more enjoyable when you participate in performance. With sails that stretch less, trimming and sail controls make a difference. Pulling on the backstay, easing the traveler or adjusting your jib car will all have the intended result in your sail. The result is a boat that moves through the water more efficiently with better motion. Your crew will certainly appreciate less heel and pitching, and you will enjoy steering more with less helm and leeway. Making sailing fun and enjoyable is a key benefit of great cruising sails.

Steve and Joy Fredrick sailing their Beneteau First 42 with 3Di NORDAC sails.

Now, I was even more confident in our product, and luckily I got the chance to share my excitement with a client. Steve and Joy Frederick have sailed their Beneteau First 42 around the Caribbean for 15 years, and they planned to meet us in Virgin Gorda for some sailing. They are outstanding sailors, whose experience and lifestyle made them great test pilots for 3Di NORDAC. In a recent conversation, Steve recalled their first passage with the new sails,

“On our first stiff upwind sail was from St. Maarten to Antigua. Under a single reefed main and roller-reefed Genoa, we were punching through 6-foot seas at 7.5 knots with a 35-degree apparent wind angle. That’s not too shabby for a 30-year-old performance cruiser!”

After two weeks of sailing with family, friends and other North Sails cruising experts, a final theme came to mind: familiarity and reliability. As you use your equipment, you gain confidence. It did not take long to develop confidence in these sails. Seeing the stability of the sail shape while pounding through waves in the open ocean was a testament to the engineering behind 3Di NORDAC, and the complete transformation of cruising sails on the market today. Cruising sailors can now expect more from their sails, and as my friend, Tim Murphy from Cruising World magazine likes to say, “Sailboats were made to be sailed.”

Originally from Los Angeles, CA, Author, Bill Fortenberry, is the Global Market Segments Manager at North Sails and a lifelong sailmaker.

READ MORE

READ MORE

news

3Di NORDAC: THE DACRON CRUISING SAIL REINVENTED

3Di NORDAC: The Dacron Cruising Sail Reinvented

Newport, RI (June 1st, 2017) – North Sails, the worldwide leader in sailmaking, introduces the latest application of their patented 3Di technology – a revolutionary cruising sail made of 100% polyester fiber. 3Di NORDAC is an innovative product that marries patented 3Di shape holding technology with the toughness and affordability of polyester sails. Tailored for small to medium sized cruising boats, 3Di NORDAC transforms polyester fiber into seamless, one-piece sails that are uniquely strong, beautiful and long-lasting.

Dan Neri, CEO North Sails, said: “We believe that great performing sails directly enhance the quality of the time our customers spend on their boats. This is as true for daysailing and coastal cruising as it is for voyaging or ocean racing. We looked at the products being offered for day sailors and coastal cruisers and saw an opportunity to do better. By combining the structural concepts of our 3Di molded composite construction process with the properties and good looks of traditional Dacron, we can now offer white sails that have a locked-in aerodynamic shape and stay flat as the wind increases.”

For thousands of years, sailcloth has been made by the ancient process of weaving fibers into a finished material. For over 60 years, woven polyester (Dacron) has proven to be the fiber of choice for cruising sailcloth – providing low cost and structurally durable sails. Today, Polyester remains a nearly perfect fiber for cruising sails due to its strength and environmental stability. However, woven sails will lose their shape long before their structural integrity is compromised, leaving their longevity and performance life out of balance. 3Di NORDAC uses a composite process which promises increased shape holding capabilities and longer structural life. Cruising sailors will now enjoy sailing with responsive sails that offer more control over their sail power – a hallmark of the North Sails cruising experience.

North Sails patented 3Di process spreads yarn fibers into individual filaments, pre-impregnated with thermoset resin, and laid into ultra thin tapes. The tapes are then interleaved in a complex multiple-axis array and thermoformed on North’s 3D adjustable molds in the sail’s unique flying shape. 3Di NORDAC sails are 100% polyester fiber, polyester thermoset adhesive, and a rugged polyester protective surface. 3Di sails have the properties of true composite structures, resisting strain and compressive forces in all directions.

Bill Fortenberry, North Sails Market Segment Manager, concluded: “Being 3D molded, the 3Di NORDAC sail is a more efficient use of materials and manufacturing, with high durability and toughness, including resilience to UV, flex, and abrasion. Along with the classic white look of traditional sails, 3Di NORDAC will ensure less heel, less helm, and less leeway for a better cruising experience. With 60 years of expertise in making Dacron sails, the science behind North’s development of top end performance sails has been applied to the new product.”

READ MORE

READ MORE

news

LA SUPERBA NAVY WINS J/24 ITALIAN NATIONALS

The J/24 class has a new Italian National champion! Thirty teams have successfully completed the 5-day regatta on the beautiful waters of the archipelago of La Maddalena.

READ MORE

READ MORE

news

OFFICIAL SAILMAKER OF THE AMERICA'S CUP

America’s Cup racing kicks off tomorrow on Bermuda’s Great Sound. In a series of events from May 26 – June 27, the 35th America’s Cup will feature six top teams battling it out for the oldest trophy in international sport.

READ MORE

READ MORE

news

TOUR DE FOIL | F4 DNA FOILING CATAMARAN

North Sails powers F4 catamaran to Bermuda and beyond

The F4 catamaran made its world debut in 2016. This exciting new 46’ one design catamaran teamed up with North Sails, DNA/Holland Composites, and other marine industry partners to support Foiling on Water, a Red Bull athlete project with Oracle Team USA skipper Jimmy Spithill. Foiling on Water sent Spithill and crew on a 932 nautical mile mission from New York to Bermuda, home of the 35th America’s Cup.

A daydream-come-true reality for Volvo Ocean Race and America’s Cup veteran Shannon Falcone, the F4 DNA project is a high-performance foiling catamaran designed with sheer speed and grace in mind. After a winter of testing, refits, and repairs in Antigua, Hull #1 is currently preparing for the 1000 nm trip back to Bermuda to join the America’s Cup spectator fleet.

“The team at DNA gave me the opportunity to propose new concepts and features that integrate my past America’s Cup and Volvo Ocean Race experiences. Thanks to the support of our partners this boat is the result of an industry-wide collaboration to help bring one-design production foiling into a real world racing environment.”

The ultimate goal of the F4 Class is to build the Tour de Foil one design racing series. Falcone and class manager Thomas Loughborough are hoping owners will be attracted to the idea of a high performance, stable foiling platform, combined with one design principles to make ownership as cost effective as possible. The F4 Class will be based out of Newport, RI in the summertime, and will enjoy Caribbean sailing in Antigua during the winter season. Their plans are to maximize the F4’s potential by pushing her to the ultimate challenges: 400 miles a day with key landing points in Block Island, Long Island, Martha’s Vineyard, and Nantucket. In the winter months, their landing points include the BVI’s and St. Barths.

World-class snowboarder Travis Rice joined the F4 crew last fall in the post Foiling On Water delivery from Bermuda to Antigua. Rice is an avid sailor who owns a 60’ Gunboat outfitted with North 3Di sails and has compared his experience to his extreme snowboarding adventures,

“I don’t know how to better describe it except for me it’s just like tree riding….I don’t know, this boat is blowing my mind.”

© Shannon Falcone

© Shannon Falcone

© Shannon Falcone

© Shannon Falcone

© Shannon Falcone

© Shannon Falcone

READ MORE

READ MORE

news

UNIQUE HISTORY OF THE J CLASS

The J Class represents an incredible blend of classic yacht and the latest advancements in modern technology

© Amory Ross

The J Class has its roots in the oldest sporting event in the world, The America’s Cup. In 1929 Sir Thomas Lipton, owner of Lipton’s (famous for his import of Lipton Tea from India), issued his fifth challenge to the Americans for the America’s Cup. He commissioned the build of the first J Class Yacht which signified the start of a new era in design evolution and racing.

The Universal Rule came into effect in 1930. The size of a yacht was determined (by waterline length) and this was shown as an alphabetical list. “J” signified yachts with a waterline length of between 75 to 87 feet. The addition of the newly designed Bermuda mast allowed the yachts to carry a huge sail plan. Nothing so large and “awesome” had been built previously.

The J Class yachts raced under the Universal Rule throughout the 1930s, which used waterline length, displacement and sail area to control the racing condition and rating of these Formula One racing yachts of their day.

Now in the present day, there is a mixture of refitted surviving yachts along with a number of new yachts built to original hull lines. Even more are planned to be built in the future. So a specific J Class handicap system was developed in order to enable all yachts built to J Class designs to race against each other regardless of size, sail area or hull construction.

The new rule is a VPP (Velocity Prediction Program) based rating system which puts limits on the performance. The aim of the J-Class Association (JCA) and the rule is to bring fair and close racing to the fleet and to give all designs a chance of winning on a handicap based system ensuring competitive, exciting and unique racing wherever this fleet goes. Combining unprecedented experience and heritage in the class, North Sails is the leading sailmaker of the J Class fleet. Reinforcing the relationship further, this year North Sails also becomes the Official Sailmaking Partner of the J Class Association.

© Amory Ross

© Amory Ross

© Amory Ross

READ MORE

READ MORE

news

J/70'S AND J/24'S SPEND EASTER WEEKEND IN COLUMBIA, SC

Thursday before the event, North Sails Tim Healy ran a J70 clinic with practice races, and on-the-water coaching followed up by a well attended debrief.

READ MORE

READ MORE

news

OFFICIAL PARTNER OF THE J-CLASS ASSOCIATION

J-CLASS OFFICIAL SAILMAKING PARTNER

Combining unprecedented experience and heritage in the class, North Sails is the leading sailmaker of the J-Class fleet. Reinforcing the relationship further, this year North Sails also becomes the Official Sailmaking Partner of the J-Class Association.

J-Class Association and North Sails are proud to announce the inaugural Kohler Cup, a trophy named in memory of Terry Kohler, former owner of North Sails, entrepreneur and philanthropist. The Kohler Cup is a season-long points championship awarded to a J-Class yacht. Over the course of the season, each yacht will accumulate points based on their results, with events bearing more significance as the season progresses. The trophy will be presented at the J-Class World Championship in Newport, RI, August 2017.

High Scoring Point Breakdown for the 2017 Season:

St Barth’s Bucket = Total Fleet x 1 point

America’s Cup J-Class Regatta = Total Fleet x 1.5 points

J-Class World Championship = Total Fleet x 2 points

“North Sails looks forward to a historical year of J-Class Racing,” said Ken Read, President of North Sails. “The Kohler Cup, like Terry himself, embodies excellence, perseverance and sportsmanship. This award is exactly what Terry Kohler was all about.”

READ MORE

READ MORE

news

INTERVIEW WITH J70 TEA DANCE SNAKE

North Sails caught up with Todd Jenner and Peter Bowe from “Tea Dance Snake”, winners of J/70 class at the 2017 NOOD Regatta in St. Pete.

READ MORE

READ MORE

news

THE NEW CLUB SWAN 50

Speed and Elegance: The new Club Swan 50 Nautor’s Swan and Juan Yacht Design collaborate with North Sails and Southern Spars to create optimal performance out-of-the-box.

Nautor’s Swan, along with naval architect Juan Kouyoumdjian, have conceived a new 50ft yacht. The Club Swan 50 places great focus on

performance while staying true to the company’s world-renowned craftsmanship and attention to detail.

For customers that are looking for a racing class with something special, this boat will satisfy their expectations and more. When a well-known builder like Swan debuts a performance yacht it creates a high level of expectation throughout all levels of the industry. New performance boats like the Club Swan 50 must be fast out of the box with little or no lead time available for testing and sail refinement. This is where North Sails and sister company Southern Spars become instrumental in presenting the boat with a cohesive package that exceeds the high expectations of a new owner.

North Sails was approached by Nautor Swan and JYD to collaborate throughout the hull, rig, deck, and sail design. Participating in the early stages of design ensures accuracy not only in sail geometry details but in anticipating important aspects of performance that ultimately would affect the sails, such as deck layouts that support efficiency, and the overall balance with hydro foils matching the airfoils (or sails) above the deck. With the results of this collaboration in hand, North designers then identify how the major variables (such as spars, sails, and appendages) integrate to produce expected levels of performance throughout the wind range.

The North Design Suite of computational tools have been used successfully in this process for the past 20 years, and repeatedly refined through projects on a wide variety of boats, ranging from small keelboats, America’s Cup, to maxis. The process is a large contributor to the success of North Sails in all major classes. Of course, there is design and there is the reality. An important part of the design process is incorporating a group of on the-water experts – people who handle the products frequently and know how boats of similar spec behave in rough to light conditions and on different angles of sail.For the Club Swan 50, a big part of this discussion was driven by the durability of the sails and their ability to retain their shape through an acceptable lifespan for the class. That is why all agreed on North Sails 3Di RAW as the optimal material for the upwind sails. The same attention to shape holding and durability is given to the downwind sails, resulting in a combination of Superlite and Superkote nylon styles from Contender and North’s own Xi-09 NPL DOWNWIND for the A-0. Hitting the water with an accurate VPP gives tangible results, especially to a new fleet. Generating a basic tuning guide that is ready to use on your first sail is encouraging for all new owners, who want to come out of the box with fast results and remain fast as the class grows and develops.

Expect the Club Swan 50 to be a very special yacht, both in performance and comfort! The team at North Sails is extremely grateful for the opportunity to offer a well-developed sail inventory and performance package, and to have collaborated with so many innovative and dedicated professionals in the process. We are excited to see the Club Swan 50 results on the water and the progress of the class over time. About the Club Swan 50 Nautor’s Swan keeps high standards of performance and design to best complement their classic models throughout the racing and cruising range, making them great boats for the “all around” sailor.

They have pushed the limits of this concept a bit further with their newest model design, the Club Swan 50.

By enlisting the competitive edge of JYD, the 50 would be decidedly fast, elegant, and within one design parameters. In the end, the specifications are innovative, providing ample opportunity for competitive sailing while still having the optionality to transform the boat to comfort, even cruising mode. The hull reflects modern Swan models with a beam-y transom, reverse bow, clear-cut chines, aft sections, and shortened freeboards. A steel blade keel, lead torpedo, and dual rudders give a more balanced configuration, and a forward center of gravity gives the Club Swan 50 significant advances in overall speed while sailing downwind and when reaching.

Learn more about the boat at clubswan50.com

Technical Specifications:

Length overall: 15.24 m or 50 ft

Length of waterline: 14.00 m, 45.93 ft

Length overall with bowsprit: 16.74 m, 54.92 ft

Beam max: 4.20 m, 13.77 ft

Draught: 3.50 m, 10.49 ft

Ballast: 3,400 kg, 7,495 lbs Displacement (light): 8,500 kg, 18,739 lb

Sail upwind (TBD): 142 m², 1528 ft²

Sail downwind (TBD): 296 m², 18739 ft²

Designer: Juan Kouyoumdjian

Construction: OY Nautor AB, Finland

Full carbon: Hull, deck, mast, boom, rudders, bowsprit

READ MORE

READ MORE

news

2017 J70 MIDWINTERS RECAP

The J70 Midwinters this past weekend were an all around success for North powered teams. Light air made for tough conditions-and a ton of patience.

READ MORE

READ MORE

news

THE SCIENCE BEHIND YOUR SAIL TRIM

Part 1: Induced Drag and Mainsail Leeches

By Tom Whidden

One of the goals for our book, The Art and Science of Sails, is to connect the theoretical with the practical. An understanding of the physics of aerodynamics will help us better trim and set our sails. To illustrate this, I’ve chosen a seemingly obscure topic – induced drag and how to minimize it – by splicing together a few excerpts from my new book.

As a tactician, I need to ensure the boat is fast. Otherwise, we’re not going to win, regardless of how well I do my job. And, since the main was always front and center for me, I was constantly studying it, ensuring my mainsail trimmer was doing his/her job. I hope the following will help you better understand the connection between the science and sail trim—and there’s plenty more detail in the book.

********

By far the largest and most destructive drag for sailing performance is induced drag. The root cause of induced drag is the changing of the direction of the air flow by the foil. With airplane wings that change is downward; with a sail it’s to weather. The change in flow direction is the beginning of the process of lift.

So, induced drag is a direct result of the creation of lift. In more technical terms, induced drag is the varying coefficient of lift (Cl) across the span. In other words, the differences in lift across or over the total area of a sail or wing cause induced drag.

How does induced drag relate to real life on a sailboat? Assuming the boat is well trimmed and properly set up, about 80 percent of the total sail area will experience relatively constant Cl. However, in the aftermost 20 percent of the sail, the velocity of the flow rapidly decreases; and with it, the lift. The rapidly changing Cl results in significant induced drag, some on the leech and some at the head and foot. This induced drag forms the vast majority of the total drag.

There are two variations of induced drag: off the trailing edge (leech), and off the tips (head and foot).

This photo of Steve and Heidi Benjamin’s SPOOKIE shows the leech twist on the mainsail quite well. © Onne van der Wal / North Sails

Induced Drag off the Leech

These are vortices, spinning counterclockwise off that trailing edge. A deeper head section, compared to the bottom, minimizes the flow of air trying to find the shortest path from the high-pressure windward side to the low-pressure leeward side.

Leech twist is very significant for the optimization of upwind speed. It’s been said that the only reason to have a front of a main is to be able to attach the leech area to the mast! The leech of the main, however, is there not just to ensure that the air bent around the front of the main is allowed to exit with the least interference (induced drag), but to help steer the boat.

So, how should the trimmer adjust the leech to best attain the above two goals while sailing upwind? With a well-designed and relatively new main, the answer is to sheet the main until the top telltale (preferably hanging off the back of the top batten) just begins to stall. If it’s constantly stalled (hidden to leeward), it’s a sign drag is too high. The lift-to-drag (L/D) ratio is lowered. If the telltale is flying straight back or there is an excess of backwind, it’s a sign that the sail could be sheeted tighter to allow the boat to sail closer to the wind. In this case, the L/D ratio is reduced for the opposite reason.

This screen shot, from a RANS-code CFD analysis, illustrates the tip vortices emanating primarily from the top leech of the main on a fractional-rigged boat. The orientation is looking back at the top of a rig an sails from just to leeward and forward of the onset flow.

Induced Drag off the Head and Foot

The second variation in induced drag is tip vortex. On a plane, these flow off the ends of the wings; on a sail, they flow off the head and foot. There is a pressure difference, or delta, from the lee side of the sail to the windward side. Nature abhors pressure deltas. It’s why we have wind. And, it’s why the flow on the high-pressure side of a sail wants to escape over the top or end to help equalize this pressure.

Almost all modern race boats employ a fractional rig. At the hounds, the main’s chord on the fractional rig is still quite long and therefore helps shed the headsail’s tip vortices. On a masthead rig, the tip vortices of the headsail are matched with the tip vortices of the main. Not good!

*****

We cover this topic (and many others) in much more detail in The Art & Science of Sails Revised Edition, written by myself and Michael Levitt. If you enjoyed this short overview you’ll enjoy the book even more.

READ MORE

READ MORE

news

NORTH TECHNOLOGY GROUP CEO, TOM WHIDDEN, CELEBRATES 30 YEARS WITH NORTH SAILS

North Technology Group CEO, Tom Whidden, celebrates 30 years with North Sails

February 1, 2017, saw Tom Whidden celebrate 30 years with North Sails. On this occasion, we asked the celebrated sailor to recall his years spent with North and reflect, in his own words, on the changes the company has experienced since 1987.