NORTH SAILS BLOG

Tout

Events

Guides

News

People

Podcast

Sustainability

Tech & Innovation

Travel & Adventure

news

HELIX AND THE FIGARO 3

HELIX SAILS AND THE BENETEAU FIGARO 3

A Specialized Sail Structure, Helix Is Part of the North Sails Recommended Inventory For This Foiling Offshore Class

Spend a day in a North Sails offices and lofts and you’ll quickly observe Helix sails are a hot topic. Who’s taking delivery this week, how are they performing, are the clients happy? Our sail design team is constantly looking at photos and video of sail shape, while our sales team is fielding inquiries from current and potential clients looking to step up their performance.

In the last few weeks, Supermaxi Scallywag won their class and broke a record at Les Voiles St Barth, Wally Centro Magic Carpet 3 took delivery of their new Helix sail before Palma Vela, Cao Ila R won the Mini Maxi division at Capri Sailing Week, and the feedback on Helix sails from the Beneteau Figaro 3 class is coming in fast and furious.

“The data is coming in after a few months, and the Helix sails have less sag, less load and are faster on every angle than the competition,” North Head of R&D Gautier Sargent explains. “The results from the Figaro 3 are proof that the performance gains we advertise are real.”

Helix sails are a specialized sail structure evolved from Load Sharing Technology, and are part of the North Sails recommended inventory for this foiling offshore one-design class. These sails are more versatile, forward projecting and self-supporting, featuring a luff cord to fine tune the luff shape.

“Helix gives us the ability to adjust the flying shape to the conditions and point of sailing. Also, the loads required to control your sag are reduced and the overall bagged weight is light.”

Armel Le Cléac’h, Skipper Banque Populaire Figaro 3

The North design team is 80 people strong and is a powerful collection of very talented design experts with an excellent track record of developing new concepts.

“Designers at North Sails are committed to understanding the why,” Gautier says. “Paired with our obsession to deliver the best product, this has brought people back to ask about Helix. At North Sails, we look at the long game and incorporate all factors (material, design, ease of use) into our product offering.”

Though it wasn’t a popular decision initially, Gautier stands by the North Sails approach of building a handful of identical Helix sail prototypes for the Figaro 3 fleet. This setting of a baseline is similar to how North Sails handles the IMOCA, Melges 20 and J/70 classes, and it gives teams the opportunity to test the sail at different regattas, with all factors being equal.:

“Helix is a good fit for the solo Figaro 3 because it is very versatile and covers a huge range of conditions and wind angles. You can easily switch from reaching to a downwind sail.

Morgan Lagraviere, Skipper Safran IMOCA

“We lost a few guys at the beginning because they wanted custom sails, but building the best sail we could for this class, and offering it to everyone was what we did,” explains Gautier. “We want our clients to feel special, but we don’t like to play favorites. If everyone is the same when learning the boat, you understand whether you are faster because of different trimming, a different setting on the foil, or maybe different sail configurations.”

© Alexis Courcoux

READ MORE

READ MORE

news

LA SOLITAIRE PASSE À L'AIR DU FOIL ET DU 3Di

LA SOLITAIRE PASSE À L’AIR DU FOIL ET DU 3Di

47 skippers à bord de leur tout nouveau Figaro Bénéteau 3 sur la ligne de départ

© The Solitaire URGO Le Figaro

L’épreuve maîtresse des Figaristes pour cette saison 2019 approche à grands pas. La Solitaire – Urgo Le Figaro sera lancée dimanche 2 juin à Nantes, destination Kinsale en Irlande pour la première étape, puis direction Roscoff et Dieppe en France pour les trois étapes suivantes. 47 skippers à bord de leur nouveau Figaro Bénéteau 3 à foil dont un tiers est équipé de voiles North Sails seront dans les starting blocks pour espérer décrocher la victoire de cette 50e édition. Evénement phare de la course au large en France, la Solitaire du Figaro est considérée comme une compétition éprouvante et exigeante tant sur le plan psychologique que physique ou tactique. Ténacité, dépassement de soi, rigueur et vigilance sont quelques-unes des compétences à user durant cette prestigieuse épreuve en solitaire du circuit Figaro. D’autant que cette année, le défi est de taille avec une palette de spécialistes déjà vainqueurs de l’épreuve comme Armel Le Cléac’h qui vient de remporter la Solo Concarneau, Jérémie Beyou, Yann Éliès, Alain Gautier ou encore Michel Desjoyeaux.

© Jérémie Beyou/Charal Sailing

Pour certains concurrents, cette Solitaire représente l’occasion de continuer à régater à haut niveau en attendant la construction de leur nouveau Imoca ou Ultim, de naviguer sur un support monotype dans un autre format de course et surtout de gagner en assurance et performance. Le défi pour l’ensemble de la flotte reste encore la maîtrise de ce monocoque à foil nouvelle génération et l’anticipation des conditions météo sur un parcours technique de plus de 2100 miles. En tout cas, ils donneront tout et ne lâcheront rien !

La première édition de la Solitaire du Figaro a vu le jour en 1970 et s’appelait alors la course de l’Aurore, organisée par le journal du même nom. En 1980, Le Figaro achète les droits de l’événement et rebaptise la compétition qui porte désormais le nom du groupe.

Pour plus d’infos.

READ MORE

READ MORE

news

INTRODUCING THE RJF RADIAL LIGHTNING JIB

NEW RJF RADIAL JIB FOR THE LIGHTNING

The Perfect Match For The MF-2 Fisher Mainsail

For years the question of “what’s new” for Lightning sails has been answered as “not much”. Today there is a new answer.

Following the heels of the success of the V17 Radial jib, the North Sails Lightning team has developed a new radial jib that sets and trims to match with the MF-2 (Fisher) mainsail. After extending testing, we are excited to introduce the RJF Radial Lightning jib.

North Lightning expert Brian Hayes explains about the new sail, its development process and the success it has had on the race course:

“We had been working on radial panel layouts on several of our designs for a few years. Ched Proctor went through several test runs as we developed the successful V17 that is designed to match up with the M-5 main tuning system. We had been pushing for a “radial” layout for the MF-2 setup as well with the goal of developing a sail with similar shape as the JF-2 jib, using a radial construction to maximize the ability for the sail to hold its designed shape, for ultimate durability.”

The orientation of the cloth panels is a big deal in Dacron sails. Getting the shapes to do what we wanted takes time and extensive testing. “I’m really pleased with how the sail flies and the boat speed has been really good.”

The goal was to develop a jib with similar shape as the JF-2, using a radial construction to maximize the ability for the sail to hold its designed shape, for ultimate durability.

When final RJF version was completed (October 2018) Brian took it to the Charleston Wild Oyster, snapped it on Steve Davis’ boat and they won the event. “We still wanted to look at it some more at the Kings Day Regatta. I convinced Ched to use it with an MF-2 mainsail (I know… gasp!) and he won that event as well. A couple of clients noticed the sail and asked if they could buy it to try. In that short period of time those teams reported two second place finishes in two regattas. We felt confident the RJF jib was fast.”

Brian Hayes is heading to the World Championship in Espoo, Finland sailing with Steve Davis and Laura Jeffers. Then they head to the North Americans in Buffalo in August. They will have a new RJF jib in their inventory. “We are hoping we have as much luck as we did in Charleston” said Brian.

Shop Lightning sails.

READ MORE

READ MORE

news

NEW HIRE STRENGTHENS SENIOR MANAGEMENT TEAM IN FRANCE

NEW HIRE FOR NORTH SAILS STRENGTHENS SENIOR MANAGEMENT TEAM IN FRANCE

Philippe Touet Joins North Sails France as General Manager

Philippe Touen

North Sails have announced Philippe Touet as the new General Manager of North Sails France. Previously the Commercial Director of Incidence Sails, Touet is now responsible for sales management and operations of the North Sails business in France. In this senior management position, Touet will work alongside Gautier Sergent who will provide strategic leadership in his expanded role as a Director of France. Philippe will join North Sails from June 17th, 2019.

“North Sails is the industry and technology leader with their constant innovation and development” Touet commented. “North Sails understands their clients’ needs, whether they be Grand Prix racers, Superyacht owners, cruisers or One Design enthusiasts. I am looking forward to working with Gautier and the entire North Sails team to continue the success the brand saw under the direction of Greg Evrard.”

“Philippe’s combined sailing and management experience make him an ideal fit for our business and company culture,” says Sergent. “His charismatic personality, as well as his deep knowledge of the industry, convinced us that he was the best candidate to help take North Sails France forward. He is well respected within the industry and we’re fortunate to have him join North Sails.”

Touet joins a strong management team based at the North Sails manufacturing and sales site in Vannes, France. Opened in 2004, this location is a sales and service resource for local sailors and an innovation hub for sailing’s most exciting offshore projects including the Ultim, IMOCA, and Figaro 3 classes.

READ MORE

READ MORE

news

EIGHT ONE DESIGN EXPERTS PUT TECHNOLOGY TO THE TEST

EIGHT ONE DESIGN EXPERTS PUT TECHNOLOGY TO THE TEST

World Champions Team Up For J/70 Telemetry Testing

Recently in San Diego, a group of one-design champions with 11 world titles between them came together for an intensive J/70 sail-testing session. The primary goal was to quantify whether new upwind sail designs would prove faster than the existing J/70 inventory, which has been on the podium at every class world championship so far. Tim Healy, President of North Sails One Design, explains it this way: “We wanted to look at some different concepts and either prove that we’re on the right track or cross some ideas off the list, to further advance the performance of our sails.”

A secondary goal, Tim says, was to better understand the existing designs and how tuning and trim plays into performance. “A sail design can be improved, but unless you understand how to trim and tune it properly, you’re not going to get the benefit. Our current designs are very good, but we also wanted to make sure we’re really getting the most out of the sails.”

With these goals in mind, Tim invited one-design experts from a range of competitive keelboat classes to go sailing and then brainstorm ideas for improvement. Mike Marshall put his own worlds-winning drive to work as the telemetry expert, coach, and debrief leader. “My goal is to not be the most vocal person in the room,” Mike says, “but to be the person who facilitates. Trying to get the best input out of every single person.”

A sail design can be improved, but unless you understand how to trim and tune it properly, you’re not going to get the benefit. Our current designs are very good, but we also wanted to make sure we’re really getting the most out of the sails.

How It Worked

Each morning before leaving the dock, the two J/70s were tuned to the same base numbers, and teams of four were carefully combined to be within ten pounds of each other. Tim Healy and Will Welles steered. The group sailed in both the flat water of South Bay and outside in ocean swells, in breeze that ranged from five to thirteen knots.

On each of the four days Mike ran a series of five-minute telemetry runs, using the proprietary equipment he helped to develop, which has set new standards for sail testing. Running up to twenty-two tests each day built an impressively large data set of accurate VMGs for each boat. Skip Dieball, who trimmed for Tim Healy’s team, had used the telemetry to prepare for his win at the 2015 Etchells Worlds. “It was incredibly valuable in determining the fastest setup and fastest equipment combination.”

Having world champions as rail meat, Tim says, was a lot of fun. “They are so competitive! On every test, everyone was doing everything they could to try to win the test. Then in the end, Mike would tell us who beat who.”

A Potent Mix Of Personalities

After sailing, the two teams got together for a debrief to share thoughts about the results. A discussion with so many champions led to surprising insights each day, Mike explains. “Put nine competitive sailors in a room together, and you come to a lot of really good conclusions. Everyone brings their own experience. Zeke Horowitz brings his Flying Scot and his J/22 experience. Eric Doyle brings his Star experience. Will Welles brings his many years of J/24 sailing and Skip Dieball, his Etchells and many other one-design classes success. Vince Brun has 40 or 50 years in this business, and he’s always got something very valid to say as well as always being an absolute pleasure to have around. Tim Healy brings his encyclopedia of knowledge of all the things that he’s won. It’s highly beneficial to get all the different opinions and thoughts and combine the various viewpoints.” Skip Dieball was also impressed with the debriefs: “World champions everywhere! It was fun to collaborate and discuss what we felt, how we set up the various designs.”

Put eight competitive sailors in a room together, you come to a lot of really good conclusions.

Tim agrees that the wide range of perspectives helped everyone improve. “Eric Doyle, for instance, is a hands-on guy. When it comes to manufacturing, it’s always great to bounce the idea off him: ‘Hey Eric, what do you think?’ Then he says, ‘We already tried that with this class. It didn’t work.’

“Mike is the technical guy,” Tim continues. “And Zeke is more of a seat-of-the-pants guy, so it’s refreshing to hear his point of view. They all shared different experiences with sail development programs, what’s worked and what hasn’t. There were so many different talents at that table that you could always find somebody to say, ‘I can help with that.’”

What They Learned

Sail testing is all about making better sails, and Tim says that, while looking at new shapes and more user-friendly construction techniques, they took the time to drill down to the tiniest of details: the shape of a telltale window, the placement of a tack grommet, how the webbing is attached to the head of the jib. “We could talk all day about batten pocket construction and come up with examples from another class.”

Both Tim and Mike agree that if they had the four days to do over again that they wouldn’t change a thing. Eric Doyle says the telemetry was so helpful that he would never go sail testing without it again, though it falls to Mike to explain why. “We’re constantly trying to improve our sails, but at the end of the day, how do you do that? With telemetry testing, you end up with a solid, concrete answer, an indisputable fact. 85% of the time, those facts are confirmed by what people feel on the boat. When they aren’t, you can look further into why.

“Of course, I have opinions about which sail is better and why,” Mike continues. “But the two-boat testing system keeps it scientific and organized. It really pushed our development path forward, giving us answers as well as new questions to ask.”

Tim agrees that the scientific approach left him confident about their conclusions. “The bottom-line goal is to prove that we’re making a better sail. We had some good concepts that we got more data from. And we now understand the tuning and the trim even better than before.”

A three-time World Champion himself, even Tim was a bit overwhelmed by the amount of expertise they gathered together. “I know these guys. I talk to them every day. But when you stop to think about it, the knowledge base is pretty impressive.”

The bottom-line goal is to prove that we’re making a better sail. We had some good concepts that we got more data from. And we now understand the tuning and the trim even better than before.

READ MORE

READ MORE

news

CRUISING SAIL PERFORMANCE - 3Di NORDAC

CRUISING PERFORMANCE: 3Di NORDAC Q&A

What To Know About This Innovative Cruising Sail

Q: How is 3Di NORDAC different than my old cross-cut dacron sails?

A: 3Di NORDAC transforms the same trusted polyester materials of a traditional dacron cruising sail into a unified composite structure. Instead of seaming and stitching together panels of woven sailcloth, 3Di NORDAC sails are molded into a one-piece seamless sail. Like woven polyester, 3Di NORDAC sails are durable – but have better shape holding and shape longevity. If you like sailing your boat sail to its full potential, you will love 3Di NORDAC.

Q: I don’t understand how you “Mold” a sail? What’s the deal?

A: Your sail is built in its three-dimensional flying shape. All of the component materials are laid up and then fused on a full-size “mold” custom-shaped to your sail design. This process is different than cutting panels of sailcloth with curved edges and sewing them together, which is how traditional cruising sails are made.

Q: Why is a Molded sail better than a paneled sail?

A: All of the material is assembled in a precise 3D form, which means the sail will have a smoother sail shape. Also, a molded 3Di sail is better at resisting stretch and distortion because all the filaments are aligned with both strain and compressive loads. All of these materials are laid up in a multi-axis array and variable density. In panel cloth, you only have two directions that the fiber can be aligned. With 3D molded sails, there is an infinite number of alignments available to achieve the perfect shape and strength for the intended use. By better utilizing materials properties, 3Di NORDAC sails will go farther and faster.

Q: 3Di seems cool, but how do you know it will be right for cruising sails?

A: 3Di technology has sailed millions of miles over the past ten years, and over 3000 3Di NORDAC sails are in use around the world in the harshest sailing environments. We spent over two years developing 3Di NORDAC, using a scientific approach that enables predictable results. We stand behind our products and guarantee you will have great durability and great performance.

Q: I have heard Cruising Laminates don’t last long. Will 3Di NORDAC delaminate?

A: No. One of the key attributes of 3Di construction is that it is not a laminate and there is no mylar film. 3Di NORDAC is made much like a fiberglass sailboat, with a solid core of fused polyester. These spread filament tapes are bonded with thermoset polyester resin into a single structure that is heat, humidity, and UV resistant.

Q: What is the square pattern on 3Di NORDAC sails? Are these seams?

A: No, they are not seams. The outer layer of 3Di NORDAC is a special protective surface of spread filament polyester tapes. This layer resists damage from UV, chafe, abrasion, and flex. One side is oriented vertically, the other horizontally, creating the cross pattern. We think it looks cool, too.

Q: How can I trust North Sails to build a great cruising sail? Aren’t you guys are all about racing and superyacht sails?

A: It may surprise you to learn North Sails has also been the world’s largest cruising sailmaker for many decades. While we occasionally brag about our racing success, many of our North Sails team grew up cruising just like you. We like to cruise and we know how to make great cruising sails. Also, one of the benefits of building sails for around-the-world racers and superyachts is that lessons we learn about durability are directly transferred to ALL of our cruising sails.

Q: If 3Di NORDAC is such a great sail, how can North Sails offer them at affordable prices?

A: A few reasons. 3Di NORDAC is a smarter way to build sails. From a manufacturing perspective, it is like a “farm to table” approach. The materials are made into a complete sail within a single North Sails factory, with less processing. Woven polyester undergoes many manufacturing steps in a long supply chain and passes through different factories to become finished sailcloth. There are numerous embedded process and transport costs in woven dacron sailcloth. Since we are using the same base polyester fiber and making a sail in fewer steps, we can offer an affordable price and exceptional value. Also, we want to spread the word about what good cruising sail performance means. Get in touch today and Request A Quote.

Q: I love my new 3Di NORDAC sail. What should I do at the end of the season?

A: 3Di NORDAC sails require minimal maintenance, but it is always a good idea to take them into our service sites for an annual checkup. We will make sure there are no wear points, and repair any minor damage that may occur. Every 3Di NORDAC sail comes with 1-year free sail care, so bring it in at the end of the season.

READ MORE

READ MORE

news

NUEVA MAYOR PARA LOS J70

Desarrollada específicamente para palos Selden o Southern Spars, ofrece un diseño más plano y equilibrado para adaptarse a la flexión del palo en todas las condiciones.

READ MORE

READ MORE

news

SCALLYWAG ADDS HELIX, RESETS PERFORMANCE POTENTIAL

A NEW NORMAL FOR SCALLYWAG

Helix Sails Create Higher Expectations

📸 Les Voiles St Barth Richard Mille

The 100’ super maxi Scallywag added Helix to their sail wardrobe in early April, just in time for Les Voiles de St Barth Richard Mille regatta. With limited testing days from install to start line, it was trial by fire.

“Scallywag switched over to North Sails at the end of 2018, and we are all thrilled with the decision we made,” remarked David Witt, Scallywag skipper. “Our team has set lofty goals and our boss wanted to make sure we have every opportunity and best shot to hit them. These new Helix sails have reset our expectations for boat speed, and we haven’t even fully unlocked its potential.”

Designing the team’s new 780 sq. meter A-3 was a groundbreaking and collaborative team effort involving North designers around the world. New Zealand-based sail designer Magnus Doole led the project, which included Mickey Ickert, Mike Schrieber, Steve Calder, and Brodt Taylor.

“Helix sails represent a very exciting new style of sail design and set up,” explained Doole. “Mike and I designed the base mold and ran refinements to the design through our North Design Suite; Spiral/Desman/WARPS/Membrain/Flow. Brodt and Steve were involved from a layout perspective, and Mickey acted as my sounding board and provided a feedback loop for this really intense project. All the while, I was checking in with Steve and JB Braun on their Helix design experience to date. Sail evolution brings out the best in North Sails as the collaborative work takes the guesswork out of the end product.”

North Helix sails with Load Sharing Technology are changing the narrative on the sail design and set up, and stepping into a whole new world of headsail performance. Get in touch with a North expert today and learn how Helix can help you raise your game.

https://www.northsails.com/sailing/wp-content/uploads/2019/04/Scallywag.mp4

READ MORE

READ MORE

news

NEW GENERATION 3Di JIB FOR THE MELGES 20

NEW GENERATION 3Di JIB FOR MELGES 20

New 3Di Ji-4 Jib Now Available Across The Fleet

The One Design team at North Sails are never satisfied; they are continually striving and working to improve their products and provide their clients with the tools to raise their performance levels. Such is the case in Melges 20. Two years after first introducing 3Di technology to the class, North Sails are releasing a cutting edge 3Di jib to create a hugely competitive 3Di sail wardrobe across the boat. It was this 3Di mainsail and jib combination that saw STIG triumph in dramatic style in the recent World Championships in Miami. North Sails clients may have won the Melges 20 World Championships for the last seven years, but this does not mean the team rests on their laurels.

Over the winter, the experienced Class Leader Giulio Desiderato, worked with Europe’s leading designers and STIG to roll out the Ji-4. Developed by Giovanni Cassinari and Michele Malandra, with the help of One Design expert Mike Marshall, the team used North’s bespoke Membrane software to simulate the sail structure and design. Testing through February and March evolved a sail that ultimately powered STIG to victory in Miami.

“Simulating the data collected from the North team racing on the circuit with our in-house software, we were able to create a new generation of jib”

Commenting on the new 3Di jib, Giulio Desiderato added, “It was a dream team of designers with Giovanni, Michele, and Mike, and they did a fantastic job, working hard to create something really exciting. Our 3DL jib was a big success with our Melges 20 clients, powering many victories on the circuit, so we wanted to develop a 3Di jib that would be even more successful and work perfectly with our 3Di mainsail. Simulating the data collected from the North team racing on the circuit with our in-house software, we were able to create a new generation of jib with a completely changed layout, modified shape and new sail geometry. The sail is not only lighter, but the 3Di structure makes it more stable, and the new layout combines perfectly to produce a fantastic shape that delivers.”

The skipper of STIG, Alessandro Rombelli summarized the performance of the new jib: “The new 3Di for the Melges 20 is much more effective. The shape holds perfectly and is desirable in all conditions. The new 3Di Ji-4 jib was a great tool for our upwind performance.”

Giulio concluded, “This project really shows the potential when the unparalleled North Sails network combines the best experts in different fields to deliver a game-changing sail. I am excited about offering our clients this new product, and we won’t stop there, we’ll always keep looking to improve. I want to thank all the owners and sailors that bring so much energy and passion in deciding to work with us to reach our shared goal to constantly improve, and sail faster and faster.”

The new Ji-4 is now available for order and will be ready for delivery ahead of Act 2 of the World League. To learn more, please visit our class page.

READ MORE

READ MORE

news

NOUVELLE CLASSE DOTÉE DE VOILES NORTH SUR LE SPI OUEST

NOUVELLE CLASSE DOTÉE DE VOILES NORTH SUR LE SPI OUEST

© Giovanni Mitolo

L’incontournable épreuve de voile du week-end de Pâques réitère son rendez-vous annuel pour la 41ème fois. Le Spi Ouest-France Destination Morbihan se disputera sur quatre jours du 18 au 22 avril 2019 à la Trinité-sur Mer en baie de Quiberon. Ce grand rassemblement trinitain réunira de nombreux passionnés de voile, professionnels comme amateurs, répartis sur différentes catégories de bateaux, du monocoque au multi en passant par les voiliers de séries IRC et les monotypes.

ETF 26 : Nouveau Souffle sur le Spi Ouest

Cette année, les organisateurs apportent un nouveau souffle à la compétition en ouvrant les portes à une toute nouvelle flotte de catamarans volants en carbone : les Easy to Fly ou ETF 26. Ces sport boats à foils de 7,93 mètres, dessinés par Guillaume Verdier et équipés de voiles North Sails, ont été conçus par la société Absolute Dreamer de Jean-Pierre Dick, ancien skipper de St-Michel Virbac et quadruple vainqueur de la Transat Jacques Vabre entre autres. Les ETF 26 peuvent atteindre deux fois et demie la vitesse du vent et dépasser les 35 nœuds. Compte tenu de leur vitesse élevée, un rond de course leur sera spécifiquement réservé. Le Spi Ouest sera donc leur première régate de série. En effet, la classe ETF 26 envisage de se constituer un championnat dont l’un des objectifs est d’offrir aux navigants l’opportunité de faire leurs gammes sur un support volant en attendant la construction de leur Imoca ou Ultim.

Parmi les autres séries en lice représentées sur le Spi Ouest 2019, on trouve les Diam 24, les Multi 2000, les IRC 1 à 4, les IRC Double, les First 24, les First 31.7, les Figaro 2, les Grand Surprise, les J/70 et J/80, les Mach 6.5, les Mini 6.50, les Open 7.50 et 5.70, ainsi que les Osiris Habitable.

Depuis sa création en 1978, le Spi Ouest n’a cessé de prendre de l’ampleur en attirant un grand nombre de marins français comme étrangers. Organisé par la Société Nautique de La Trinité-sur-Mer et parrainé par le quotidien Ouest-France, cet événement populaire est aujourd’hui considéré comme la plus grande régate de voiliers habitables en Europe. Plus de 420 bateaux et des milliers de régatiers s’affronteront pour l’occasion dans des conditions météo prévues favorables. De quoi réjouir concurrents, visiteurs et organisateurs.

READ MORE

READ MORE

news

OPTIMIST R&D

Making the square-bowed Optimist go fast requires a different thought process, North Sails expert and J/22 World Champion Mike Marshall explains.

READ MORE

READ MORE

news

MIKE MARSHALL: WORLD CHAMPION & SAIL DESIGNER

MIKE MARSHALL: WORLD CHAMPION & SAIL DESIGNER

Looking Towards A New Challenge

Design expert Mike Marshall joined North Sails in 2013 because he wanted to combine sailing with working in aerodynamics. “The two mesh well in designing sails,” he says. Working with the North Design Suite and learning from JB Braun was a great opportunity, and “the job stays fresh because each challenge is new and different.” After a few years commuting from his home base in Rhode Island to JB’s office in Marblehead, MA, he’s now based out of the Portsmouth loft, which has expanded to include a small design team.

Mike also coaches youth sailors, which has helped his latest design project: refining the North Sails Optimist inventory. “The coaching experience allows me to relate to the sailors to get quality feedback.” Combined with his sail design expertise, he can then interpret that feedback based on what he’s seen on the water.

© Charmaine Gittens / North Sails Leading Edge Optimist Clinic

Opti sail design is a unique challenge, he continues. “The designs are based on weight ranges and we get calls from people who say, ‘Well, what if my kid ate a big breakfast sandwich?’ Really, the important thing is that the sail works and that the sailor can use the same shape sail for a significant amount of time.”

When he looked at existing designs, Mike realized that sprit tension is the biggest driver of sail shape. “Most coaches just tell their sailors, ‘make the wrinkles go away,’ but there’s a lot more to it than that.” The new design is radial in the clew, which makes it possible to adjust sprit tension to a wide range of conditions. “I think of it as a halyard; more tension closes the upper leech. Closing the leech when you are hiking and not overpowered—that’s really powerful. Yes, you can get rid of the wrinkle by pulling more tension, but removing the wrinkle is not really what you’re trying to achieve.”

“The job stays fresh because each challenge is new and different.”

Mike’s own sailing currently focuses on world-level one-design racing, mostly in small keelboats. He recently won the J/22 Midwinters, and in 2016 won the J/22 World Championship. He’s also done well in the J/24, J/70, and VX-One. Making keelboats perform definitely helps his design work, Mike says. “In both design and racing, the details are really important, but I try not to get too caught up in the small stuff and focus on doing the big things well.”

As for hobbies, Mike laughs at that question. “Sailing?” he quips, before adding that “kiteboarding and diving are definitely hobbies, not that I get to do them that much these days.”

© Charmaine Gittens / North Sails Leading Edge Optimist Clinic

READ MORE

READ MORE

news

INTRODUCING THE NEW F-1 MAINSAIL FOR J/70 CLASS

NEW F-1 MAINSAIL FOR J/70 CLASS

Flexibility, Versatility, Balance, And Speed

The One Design team at North Sails are driven by our commitment to find solutions for our customers and to always find more speed and boat performance. This is why the new F-1 mainsail was tested and developed within the competitive J/70 Class and why it is now available to everyone. Developed to fit the Selden mast or a Southern Spars mast with a stiff set-up, the F-1 mainsail is a flatter design, balanced top to bottom to match mast bend in all conditions. Designed to be user-friendly, the F-1 is easy to trim, and tune, to produce maximum speed on the water.

“Development on the F-1 main started with sail testing sessions in the early spring of 2018, using the North Sails two boat testing telemetry system,” commented North designer Mike Marshall. “Using the results data and the power of the North Design Suite, were able to, in very few iterations, come up with a sail that much more effectively fits the Selden mast. An additional benefit is the vertical shaping in the sail is much more balanced to work well through the entire range of conditions.”

Commenting further on the development of the F-1 sail, North Sails One Design expert Max Skelley added “North Sails were invited to join Bruno Paquenelli’s Team Stampede to campaign for the 2018 J/70 Worlds in Marblehead. It quickly became apparent that the standard mainsail set up is quite different with the Selden mast. Primarily, in light air they were unable to flatten the main enough or get the draft far enough back to give the boat some helm; the shape looked full and draggy. We worked with Mike Marshall to flatten the vertical profile of the sail, and after several trials, we reduced the luff curve by enough to handle the very straight fore and aft mast set up the boat required in light air. The result: a very even sail shape was achieved, with resulting balance and speed.”

“Developed to fit the Selden mast or a Southern Spars mast with a stiff set-up, the new North Sails F-1 mainsail is a flatter design, balanced top to bottom that reacts to mast bend in all conditions. Designed to be user-friendly, the F-1 is easy to trim, and tune, to produce maximum speed on the water.”

At the J/70 Worlds, in a wide range of challenging conditions, Stampede’s upwind speed was outstanding and got the team top finishes, with equally strong results in 15+ knots of wind. As North One Design expert Eric Doyle noted “With the J/70 being so tender and light, we were able to flatten the main more than ever before, and this let us put the bow down and go fast when we needed to. The F-1 main allowed us great versatility in the big fleet. We could trim hard to point and hold our lane off the starting line without stalling the sail too much.”

“The F-1 proved it was ready for market after the 2018 J/70 Worlds,” explained Tim Healy, President of North Sails One Design. “The regatta was ultra-competitive, and the new F-1 finished an extremely close second place, just a single point away from winning it all. This battle-tested result was the conclusion to our sail testing.”

The F-1 mainsail is a new cross cut design featuring less camber when compared to the North XCS-2. Standard Features include one gaff batten, two full-length battens, two leech battens, vision and spreader windows, radial teardrop patches, spreader chafe patch, trim stripes, leech telltales, Class insignia, adjustable leech and foot cords, and roll bag. The F-1 sail is now available for any team competing at Charleston Race Week or for the summer season.

READ MORE

READ MORE

news

SUPER-CHARGED COMPETITION AND HIGH PERFORMANCE SAILING

SUPER-CHARGED COMPETITION & HIGH PERFORMANCE SAILING

North Sails Teams Up With Melges For The 2019 World League Season

📸 Melges World League / Mauro Melandri

The European Division of the Melges World League racing season commences on March 29th. In an event that was designed to super-charge competition in the Melges 20 and 32 classes, North Sails is proud to continue our partnership for the third consecutive year. As the industry leader in one design sails, North Sails plays an active role in delivering great events for all the sailors joining the Mediterranean-based circuit.

The 2019 season consists of 10 events, spanning eight months. This opening act will feature the Melges 32 class sailing on crystal clear waters in Villasimius, Italy, a venue known for its excelling racing conditions. In 2018, both Melges 32 and Melges 20 top titles were won by North powered teams; Matteo Balestrero’s Giogi securing the Melges World League title in the Melges 32 and Filippo Pacinotti’s Brontolo placing on top of the podium of the Melges 20 European Division.

📸 Melges World League / Mauro Melandri

Through our partnership, North Sails is committed to showcasing the World League events and bringing awareness to the high-performance Melges 20 and 32 classes. Melges World League content and event news will be shared across the North Sails social media channels, whose audience is unparalleled in the sailing world. In addition to sharing event news, North Sails class experts will be on hand at each event to help sailors by delivering support and collect first-hand feedback for continued product development. The combined online visibility and on-site support guarantee an enhanced experience for competitors and all fans of one design sailing.

Join Us Online:

Facebook | Instagram @north_sails @melges32 @melges20

📸 Melges World League / Mauro Melandri

READ MORE

READ MORE

news

2019 FINN INVENTORY

2019 NORTH FINN INVENTORY

Optimized Designs for Sailing Conditions, Mast and Sailor Weight

© Sascha Klahn

The North Finn inventory is customized to complement each and every mast individually. Our Finn Radial designs are manufactured from North Sails’ exclusive NLXi Technora laminate, while the Cross Cut sails are manufactured from Maxx Aramid laminate. Find below our sail selection charts which shows the sail that best suits your weight, mast and sailing conditions.

WILKE & PATA MASTS

CONSTRUCTION

RADIAL

RADIAL

CROSS CUT

WIND RANGE

0-8 Kts

5-12 Kts

8-18 Kts

15-30 Kts

All-Purpose

All-Purpose

FABRIC

NLXi-02 Technora

NLXi-03 Technora

NLXi-03 Technora

NLXi-03 Technora

NLXi-03 Technora

Maxx 06F Aramid

100+ KG

MB-1GL

MB-1G

M-1

MB-1G

M-1

MX-6

96-99 KG

MB-1G

MB-1G

MB-1G

MX-7

92-96 KG

MB-1G

MB-1G Minus

MB-1G

MX-7

-92 KG

MB-1G Minus

MB-1G Minus

MB-1G Minus

MX-8

HIT MASTS

CONSTRUCTION

RADIAL

RADIAL

CROSS CUT

WIND RANGE

0-8 Kts

5-12 Kts

8-18 Kts

15-30 Kts

All-Purpose

All-Purpose

FABRIC

NLXi-02 Technora

NLXi-03 Technora

NLXi-03 Technora

NLXi-03 Technora

NLXi-03 Technora

Maxx 06F Aramid

100+ KG

MB-1GL

MB-1G

M-1

Xi-2

M-1

MX-6

96-99 KG

Xi-2

Xi-2

Xi-2

MX-7

92-96 KG

Xi-2

Xi-3

Xi-2

MX-7

-92 KG

Xi-3

Xi-4

Xi-3

MX-8

Standard Features: Class insignia, sail numbers, vision window, Epoxy battens, elastic batten pockets, plastic headboard, leech and trim tell tales, leech line, 7mm luff rope, long roll bag, World Sailing in-house measurement and class royalty label.

Optional Features (additional cost): Carbon battens, carbon headboard, stick-on pockets, adjustable elasticated luff and country flag.

For more information on the North Finn designs or to place an order please contact your local North loft. Please have your mast bend numbers available.

READ MORE

READ MORE

news

M32 SAILING IS HEATING UP

M32 SAILING IS HEATING UP

The Road To The Worlds Is Always Exciting In These High Adrenaline Cats

📸 M32 World / Felipe Juncadella

Eight M32s will meet in Miami for the fourth and final event of the 2019 class Winter Series. A single point separates the top two boats, who have their eyes on the “Rooster” series trophy.

After Miami, M32 seasons are heating up on both sides of the Atlantic. In North America, the fleet will compete at Charleston Race Week before heading north to Newport, Rhode Island, for the NYYC Annual Regatta, the inaugural Midtown Cup. Meanwhile, the European fleet will start their season with two regattas in Italy before heading north to Holland and Sweden. Both European and North American seasons culminate with the 2019 World Championship in Riva del Garda, Italy at the end of August.

The M32 is a fast, fun, one design catamaran class. Designed in 2011, this dynamic class saw dramatic growth two years later when Aston Harald Composite, under the leadership of sailing enthusiast Hakan Svensson, acquired design and production rights. Through his involvement with the Volvo Ocean Race, Hakan knew North was the right choice to supply one design sails for the class. Since 2014. North Sails have provided fast, consistent sails for the entire class.

📸 M32 World / Felipe Juncadella

“The North 3Di RAW mainsail has been an excellent product,” said Dave Doucett, Director of M32 North America. “It’s a great value because owners are delivered a fast, yet bombproof sail that is competitive for several seasons. Class sails are built to the exact specifications of the strict one design class rules.”

With an owner-centric mentality, the class has planned a sailing schedule that provides easy logistics to amazing sailing venues. Owners in both North America and Europe are able to hone their speed and boat handling skills during a full regatta schedule in global sailing hotspots, and also close to home with their local fleets.

A strong M32 fleet is expected on the start line at the 2019 Worlds. Located at the northern end of Lake Garda, Riva del Garda is one of the best-known yacht racing venues in the world. Northerly wind in the morning and the southerly Ora kicking in the early afternoon, combined with the funneling effects of the mountains, provide the perfect flat water, strong wind sailing conditions for these high-performance catamarans.

📸 M32 World / Felipe Juncadella

Throughout the 2019 M32 European Series, manufacturer Aston Harald will have two circuit boats available. The first will be loaned to a ‘development team,’ which might be a youth, women’s, or local team looking to try a professional racing circuit. The second will be a test boat for teams coming from monohull classes who wish to experience high adrenaline racing against a mix of pro and owner-driver teams. The M32 Europen organisers can set up potential owners and teams with M32 crew, as required: Contact Mattias Dahlström: mattias.dahlstrom@astonharald.com

In North America, potential new owners and teams will have the opportunity to test sail an M32 at the New York Yacht Club Annual Regatta (June 14-16) and The Midtown Cup (July 12-14) in Newport RI. Test sailing will also be available at the North American Championships in Miami FL (November 15-17). Contact Dave Doucett: dave.doucett@astonharald.com

For more about M32 sailing in 2019

Race Schedule | M32 Web | Facebook | Instagram @m32official

📸 M32 World / Felipe Juncadella

READ MORE

READ MORE

news

STAR CLASS LEADER ERIC DOYLE

STAR CLASS LEADER ERIC DOYLE

After Three Decades, Eric Keeps Coming Back To The Star

© Bronny Daniels

Even after almost three decades in the class, 2019 Bacardi Cup champion Eric Doyle thinks there’s still plenty left to figure out. “It’s the best platform for learning about sail shape and rig tune,” he says. “There’s quite a bit of pumping and kinetics involved. And there’s a bit of keeping the rig upright as well.” Combined, those challenges have kept him in the Star boat—and, between regattas, doing long bike rides to improve fitness and focus.

Eric started sailing as a kid on the Mississippi Gulf Coast, “Because it was so bloody hot you kind of had to be on the water in order to survive.” During college in Mobile, Alabama, he sailed Stars for the first time with the local fleet. “When I got out of college and was done racing small boats, I thought that the Star was just the coolest thing ever and started racing them.”

“When I got out of college and was done racing small boats, I thought that the Star was just the coolest thing ever and started racing them.”

That led to an Olympic campaign ahead of the 1992 Games, and that in turn led to an important phone call.“Vince Brun called me and said, ‘Hey, why don’t you come work for North Sails in San Diego, there’s a great Star fleet out here. I think it’ll help your career.’ So I packed up, pulled my Star boat out here, and started working for him.” In 1999, Eric won the Star World Championship and his first Gold Star. “129 boat fleet, that was a highlight for sure.” More recently, he and crew Payson Infelise won the 2018 North Americans. “We’re feeling pretty strong right now. So, hopefully we can continue rolling along.”

© Bronny Daniels

Since first starting at North in 1992, Eric has done some big boat sailing as well, including an America’s Cup campaign with Dennis Conner and two with Oracle. But in 2017 the opportunity came to return to the Star—and to San Diego. Now, as Class Leader for North Sails, he’s brought his Cup experience back to help improve one design sails. “It’s taken me two years to get the sails where they are now. We have made some nice improvements.” For 2019, North is offering a completely new Star product line.

As class leader, Eric is responsible for identifying the improvements he wants to make and communicating them to the design team. Then he tests the sails with a tuning partner to quantify if the changes worked. “We did quite a bit in the lead up to the 2018 North Americans,” he says. “And it all turned out pretty good. We were much faster in lighter air.” (For more about the process and results, read Star Sail Design R&D)

Eric’s plans for 2019 include two regattas in Europe: the Star Europeans on Lake Garda, and the Worlds in Porto Cervo. “We’re going to try and do those, and hopefully have a good result. And keep on in the fall after that.” Because even after thirty years in the Star, Eric knows there’s still plenty left to learn.

© Bronny Daniels

READ MORE

READ MORE

news

STAR SAIL DESIGN: R&D

STAR SAIL DESIGN: R&D

Upgraded 2019 Sail Inventory Explained By Eric Doyle And Mike Marshall

© Martina Orsini

North Sails has been making fast Star sails since the very beginning. “The first sail Lowell North made, was a Star sail,” 1999 Star World Champion Eric Doyle points out. “And we’ve been refining them ever since.”

As the Star Class Leader for North Sails, Eric devoted the past two years to figuring out how to make this hundred-year-old class go just a little bit faster. Recently he proved that was time well spent with a decisive win at the 2019 Bacardi Cup. “We were really pleased with our performance throughout the wind range,” Eric explains, adding that he used the new M-25 mainsail for the entire event.

“The mast section is quite small and the sail area is quite big,” he continues. “So small changes make a big difference.

“It’s such a great platform for learning what changes you can make and the effects they have on sail shape and boat speed.”

Matching Sails to Rig and Smoothing

After a few years away from the class to work with the Oracle America’s Cup team, Eric says it took more than a year for him and his crew to get back up to speed with the top teams. “The rigs are stiffer now. So they’re a little easier to control and they don’t break as often.” That meant sails had to evolve as well. “We’ve revamped the whole product line this year.”

North Sails designer Mike Marshall adds some detail. “We matched the luff curve to the new masts and made a couple other little design tweaks here and there to really up the range of the sails, and fix some issues they were having when they would trim too hard,” Mike says. “Certain areas would be closing, so we made a couple of tweaks. And then we made some panel layout changes.”

In addition to making the sails fit on a stiffer mast section, another goal was to reduce any bumps. “Aesthetically smooth sails are key,” Mike says. “So we made a couple of changes, especially in the jibs and some detailing. Such minor things that can really cause a problem, it’s impressive sometimes how small it can be. We worked hard on that.” Also, improvements in technology have made it possible for designers to reduce weight without threatening the sail’s structural integrity. “What if we don’t like the weight of the aluminum headboard?” Mike asks. “Can we put something in there that’s going to give the stiffening but be a quarter of the weight? How do we make that smooth? You’re making the sail as light as you can, without compromising the loaded structure.” And as Eric and Mike agree, all those little changes add up to a faster Star sail.

© Martina Orsini

Sail Testing

Sail testing done right—two well-matched boats, and a coach—is time-consuming, but it’s the only way to quantify improvement. First, says Eric;

“We have to do a lot of sailing to get as fast as the top guys and feel comfortable throughout the wind range, and with our settings. Then we have to identify our weak spots, and what we think the problem and/or solution is.”

An example is the stiff mast he was using when he stepped back into the Star two years ago. “We were pretty fast in the medium conditions, but when it got really windy, we struggled to make the sail flat enough. So, we analyzed the sails with a sail digitizing program, and compared them to what we had in the past. Then we changed the sail and went back out to find the same conditions.

“We had a big problem in really light air,” Eric continues, “and we really weren’t sure if it was the mast or the sails. At the 2019 Midwinters we changed both at the same time, something we normally don’t do, but we had a pretty good idea of what was needed. The sail was a little bit knuckle forward, so we reduced the luff curve a bit. The pictures and the coaching showed us that was the thing to do.” The result? “We were much faster in lighter air.”

Eric feels lucky to have John McCausland as a tuning partner. “He’s a great sailor, former world champion. We’ve been tuning together for 20 years. I don’t like to leave the dock without him, because we’re super-efficient. We know how to set up, and make changes, and wait for each other. And he shares everything openly, so it’s really great.”

Mainsail Design Details

The M-25 mainsail

“Our standard M-25 main, we had to get it to fit the stiffer mast and not give away too much on older masts that are more flexible. It is slightly flatter then the previous M-16 model, and it has a little tighter mid-leech with a bit more twist in the top. It’s a good all-around mainsail for the entire wind range.” The M-25 is the only mainsail Eric used to win the 2019 Bacardi Cup, though it’s not the only model available.

For the lighter winds of North America, there’s a North mainsail M0-5, made entirely of minimum weight cloth. “It’s a little more powerful to help get the crew over the side a little quicker, which is key in the Star. If you can get the crew over, you’re going pretty fast.”

Jib Design Details

All of the redesigned jibs are radial, which improves both longevity and wind range. “The J-115 Full Radial Jib really excels in flatter water,” Eric says, adding that it was their choice for most days at the Bacardi Cup. “It can sheet really hard for maximum pointing.”

On one of the light days in Miami Eric used the J-6 Wave Jib, which is better in bumpy water. “It powered through the big fleet chop with ease.” He recommends the J-6 for West Coast sailing, where they often get swell overlaid with chop. “It has more power down low and a wider entry angle to help make a wider groove when you’ve got to steer around the waves.”

There’s also a J-2, “for one of those days when you’re wondering if they’re going to send you out or not in 20 or 25 knots. It’s heavier cloth and full radial construction, and it’s quite fast. It’s really nice when you don’t want to destroy your light jib-which you can do pretty easily on a big breeze day.”

North has been winning Star world championships since 1957, so making already fast designs even faster takes a lot of effort. “We’ve improved what we felt was already pretty good,” Eric says. “It’s a lot of time and testing. But I think we made some nice steps this year.”

READ MORE

READ MORE

news

NORTH SAILS AT NEWPORT SHIPYARD

NORTH SAILS AT NEWPORT SHIPYARD

New East Coast Sales Office Opens May 1 In Response To Growing Demand

North Sails is pleased to announce the opening of a new sales office in Newport, Rhode Island. Located in the heart of the vibrant Newport Shipyard, the team believes that this location will give Grand Prix, One Design, Multihull, Cruising and Superyacht customers an easy and bespoke solution for all their sailmaking needs.

The new office will work alongside the expansive North sales and service center only 15-minutes away in Portsmouth, Rhode Island. As Newport Harbor and the surrounding area are hosting even more major events, many of which are based from the Shipyard, the new office allows clients easier access to a North Sails expert. They can also drop sails off, have them repaired and pick them up without ever leaving the Shipyard. Mike Toppa, a North Sails Superyacht specialist will head up the team. A two time America’s Cup winner, Toppa combines his vast knowledge of the industry, the players, and the products available across a broad spectrum of the market making him the perfect fit for this new venture.

Mike Toppa commented: “This office in the Newport Shipyard will be an advantage for our clients. It makes so much sense to enable them to drop in to talk about their needs and their sails in a place that is so easily accessible. We believe a drop-off and pick up point here eliminates a time-consuming step and makes it easier for our customers, and gives them more time to enjoy their sailing while in Newport. It’s hugely beneficial to be at the heart of where our clients are, to ensure that we continue to understand what they need, both now and also for the future.”

“This office in the Newport Shipyard will be an advantage for our clients. It’s hugely beneficial to be at the heart of where our clients are, to ensure that we continue to understand what they need, both now and also for the future.”

Ken Read, President of North Sails, added: “Newport is a dynamic sailing hub and where our global head office is also based. It is the right time to be offering this sort of service to our clients, with so much going on this summer in Newport, including the 12 Metre Worlds, the New York Yacht Club 175th Anniversary Regatta and so many other world-class events. Our vision as a company has always been to pair industry-leading products with unmatched client support. The Shipyard office reaffirms our commitment to provide the best possible service to all types of sailors. We look forward to seeing old and new customers, and also friends and colleagues over the coming months.”

READ MORE

READ MORE

news

WHO WE ARE: RYAN LASHAWAY

My favorite aspect of the industry is the ability to meet other people with a similar passion as mine.

READ MORE

READ MORE

news

WHO WE ARE: AJ FICCARDI

I have competed in over a dozen Lake Erie Interclub regattas and ILYA Bayweek regattas. In addition to handicap racing I have raced in the J35, J24, Beneteau 36.7, and the Lightning.

READ MORE

READ MORE

news

SPEED READING: TEAM BUILDING

SPEED READING: TIPS FOR TEAM BUILDING

Forming A Team Is Just Step One

For the past three years, Hillary Noble– North’s content marketing manager— has called tactics for the Women’s Seabags Sailing Team. Successfully sailing a J/24 with six women requires a strong team, both mentally and physically.

“We’ve come a long way since the 2017 Worlds,” Hillary says of the team’s first big regatta, where they won the Yaeger Women’s Trophy. “It’s been very rewarding in many ways.” Along the way, all six women have learned what it takes to be a great teammate, in order to make their next regatta more successful than the last.

“It’s so much fun to race with these amazing women!” she says. “They are powerful, and we keep getting better together—it’s a lot of fun.”

The team competes on the J/24 circuit year-round, and they are currently preparing for the 2019 World Championship in Miami, which they qualified for at the district one championships at Kittery Point Yacht Club, NH in 2018.

“It felt great to qualify on the water for this upcoming Worlds,” Hillary says. “This has opened two spots for other women’s teams to compete.”

“We are working hard this season,” she continues. “Making sure we have the right players for each event is really important. There will be plenty of opportunities to improve and we are always looking forward to the next regatta together.”

Hillary has collected five tips that form the basis for the team’s success. They apply equally well to her day job as part of the North marketing team—or to a mixed or men’s J/24 team. As Hillary points out, “We all want to win and get the most out of our experiences together.”

© Chris Howell

Hillary’s Tips for Team Building:

Focus on your individual job. Each team member can contribute to the team’s success. Many hands make things easier!

Know your team’s strengths, make a plan, communicate it early, and put your team in situations where they can shine.

Always work together towards a common goal. Any contribution by another set of eyes is valuable. If you see something, say something.

Help each other out. Any job on the boat can get difficult from time to time. Look out for your teammates and prevent them from failing.

Debrief after each race, but keep it short. Focus on the good things; admit mistakes, and learn something from your teammates. It’s all about growing together.

© Chris Howell

© Chris Howell

© Chris Howell

READ MORE

READ MORE

news

NEW OK DINGHY CLASS LEADER

NEW OK DINGHY CLASS LEADER

Singlehanded Champion Takes Lead In Sail Development

© Robert Deaves

Charlie Cumbley came into sailing through his family. “My grandpa worked for a boat builder, and then I got started just for leisure,” he says. “I wasn’t involved in any junior race teams. I just went out and found any boats I could sail, and that’s how it progressed until I got relatively serious in Finn sailing in my late teens and ended up meeting Paul Hobson. For my sins,” he adds, laughing.

Hobson invited him to join North Sails One Design in 2006, which Charlie describes as “an awful long time ago.” Today his title is One Design Sales Manager for the UK and gets involved in “everything from Optimists to J/80s.” He’s recently been named class leader in the OK Dinghy.

By his own estimate, Charlie has won something like fifteen national championships “across a little range of vessels.” He earned a spot on the podium at many international OK events the last couple of years and was winning the 2018 OK Dinghy Europeans until the last race, when he lost a tight battle with Star champion Freddy Loof. Though he feels he has the most experience in singlehanded boats, Charlie also sails Etchells and J/70s. “Nothing gets too stale, which is quite nice. And,” he adds, laughing, “I’ve got someone else to blame.”

© Robert Deaves

OK Resurgence

When Charlie first started sailing the OK, the fifty year old class was just starting what he calls its second wind. “130 boats at the 2018 Worlds; it’s definitely on the up.” Older designs like the OK are coming back, he thinks, because people get tired of just going fast. “They like getting back into a boat where the racing’s really close and really tactical.” And unlike the Finn, “you don’t need to be a monster of a guy” to sail the OK, though there are plenty of Olympians (like Loof) in the fleet.

“Sailors who maybe aren’t quite as strong as they used to be can get involved in this class, and if they’re good, they can have some decent results. People always like doing well, don’t they?”

The OK offers enough tweakability for retired Finn and Star sailors, thanks to its origins as a trainer for the singlehanded Olympic class. The masts are carbon, “not quite as exotic as the Finn mast, so it’s not like a small mortgage to buy one, but they’re quite nicely refined now. The new boats they’re knocking out are really nice bits of kit.”

© Robert Deaves

Sail Development

The class is strong in northern Europe and also in New Zealand and Australia. Charlie says having design groups in both hemispheres helps ensure year-round progress. “They can push on things through their summer, when it’s our winter and a bit quieter, and vice versa. They give help and feedback and design input, and then I compare it to what we’re getting over here, and then we make a decision on where we go. So, there’s been quite a lot of development in 2018. The sail that won the Worlds was the Kiwi design, which was great. Our UK design was third and leading up until the last race.”

North offers three different OK sail designs, so there’s something for everyone regardless of “where you sail, how heavy you are, and how stiff your mast is.” For big events, each competitor can measure in two sails. “You could quite happily measure in a full and a flat sail, which is what I do and what other guys do. You end up with a two sail inventory.” And each design has a large crossover, he clarifies, “so that you don’t get into that situation where you’re sailing round in five knots with a sail that’s designed purely for 20 knots and pulling your hair out.”

Mast stiffness used to be a large variable, but over the last few years the masts have become more one design—which means sail design can be more refined as well. “All the sails are built with custom luff curves to fit the mast,” Charlie says, “ just like we do in the Finns for the Olympic guys. It’s pretty customizable.”

Charlie travels quite a bit to sail, so when he’s home he tries to spend as much time as possible with his wife and two kids. His older daughter is almost big enough for Optimists, which means “I’ll become an Optimist parent. Scary things happen then!”

As for the OK Dinghy, Charlie hopes to one day step on to the top of the Worlds podium—but not in 2019, since he couldn’t make it to New Zealand. “Hopefully, the Kiwi guys nail the Worlds and we’ll sit down after that and have a little chat and see things we can improve on,” he says.

“Work on through the season. With more good sailors coming in, you need to keep pushing, getting those little details right.”

© Robert Deaves

READ MORE

READ MORE

news

CROATIAN OLYMPIC GOLD MEDALIST ŠIME FANTELA JOINS NORTH SAILS

OLYMPIC GOLD MEDALIST ŠIME FANTELA LATEST TO JOIN NORTH SAILS

World’s Leading Sailmaker Recruits Olympian To Grand Prix Team

Sime Fantela (L) and Mihovil Fantela (R) after winning their gold medal in the 49’er class at the 2018 Sailing World Championships in Aarhus, Denmark.

North Sails today announced that Šime Fantela will be joining the Grand Prix segment, putting to use his experience across a range of classes. Šime will work closely with Grand Prix Segment Leader Paul Westlake, helping the design and product development teams to quantify their ongoing innovations.

After winning gold in the 470 class at the 2016 Olympics, Šime has his sights firmly set on a second Olympic gold medal in Tokyo 2020—this time in the 49er. He’s also sailing as strategist in the 52 Super Series on the newly launched Bronenosec.

North Sails Global Head of Sales John Welch commented: “We are really delighted that Šime has agreed to join North Sails. Not only is he a great sailor with a wealth of experience, but he is a huge asset to our pro sailor network, working across sail development and testing. We firmly believe that we need the best people out on the water pushing our sails to the limits and it is only in doing this we are able to give our customers what they want – the best product for whatever type of sailing they are doing. Through the addition of Šime to our team, we continue to learn from the best of the best to deliver the highest performing products.”

Paul Westlake added: “With such depth of experience and raw talent, Šime can help us develop our understanding of sailing campaigns and Grand Prix boats even further. He is an exciting, talented sailor and is quickly turning into an important opinion leader who can help us engage and inspire the younger generation of pro sailors. We believe that the North Sails team and technology can enhance his challenge for Gold in Tokyo and in turn we can learn so much from him, competing at the highest level of the sport. In order to continue to innovate we need to be challenging ourselves to think differently, and through working with Šime we see a great opportunity to do that.”

Šime commented: “I was delighted to have been asked to work with North Sails alongside my Olympic campaign. I really believe that I need to surround myself with the best possible people and to work in the best possible environment in order to become not only a good sailor, but also the most technically skilled sailor I can be. I have always been interested in the technical side of sailing and I really enjoyed making sails for myself in my campaign for Rio 2016 – I know how important it is to know everything you can about the sails you use in order to get the most out of them.”

“There is no better place to continue growing my knowledge than joining the greatest team in the world, North Sails. I am excited to be working with some of the best designers out there as well as the technically most advanced computer programs that exist. I look forward to learning more about how to apply them both to my campaign but also to help others get more from their sails and understand as much as they can about their ‘engine’.”

📸 Star Sailors League / Gilles Morelle

READ MORE

READ MORE

news

RED BULL KING OF THE AIR

RED BULL KING OF THE AIR

Counting Down To The Main Event In Cape Town, South Africa

Make sure you’re following @northkiteboarding to find out exactly what day the competition is called within the two week window, so you can watch the livestream at redbull.com.

Want to tune into the world’s most jaw-dropping big-air contest?

The Red Bull King of the Air competition, proudly sponsored by North Kiteboarding will be returning to Kite Beach, Cape Town on the 26th January, until the 10th Feb. It’s all about the amplitude as contestants go head-to-head in a “flag out” competition format. During the two week weather window riders will only face-off in the perfect conditions – wind speeds of over 30 knots are ideal for providing the perfect swell from which to boost some extreme maneuvers.

The field for 2019’s Red Bull King of the Air will be made up of top nine riders from the 2018 edition as well as nine wildcards and video entrants. After much deliberation the last nine participants have been chosen, securing their place for the showdown on the windiest day during the waiting period in early 2019.

Confirmed for the 2019 event is defending champion Kevin Langeree, as well as North athlete Nick Jacobsen. He is currently the only person in the world with a set of North prototype kites. Nick won the event in 2017, however missed out on a chance to defend his title last year due to injury.

READ MORE

READ MORE

news

HELIX SAILS WITH LOAD SHARING TECHNOLOGY

HELIX WITH LOAD SHARING TECHNOLOGY

North Sails Is Changing The Narrative on Cableless Sails

This article is republished from Seahorse Magazine, February 2019.

There are few areas of race boat technology harder to keep secret than the latest sail designs and engineering solutions. One of the hottest – and most publicly visible – areas of development right now is perfecting a cable-free headsail that not only goes fast… but that also lasts.

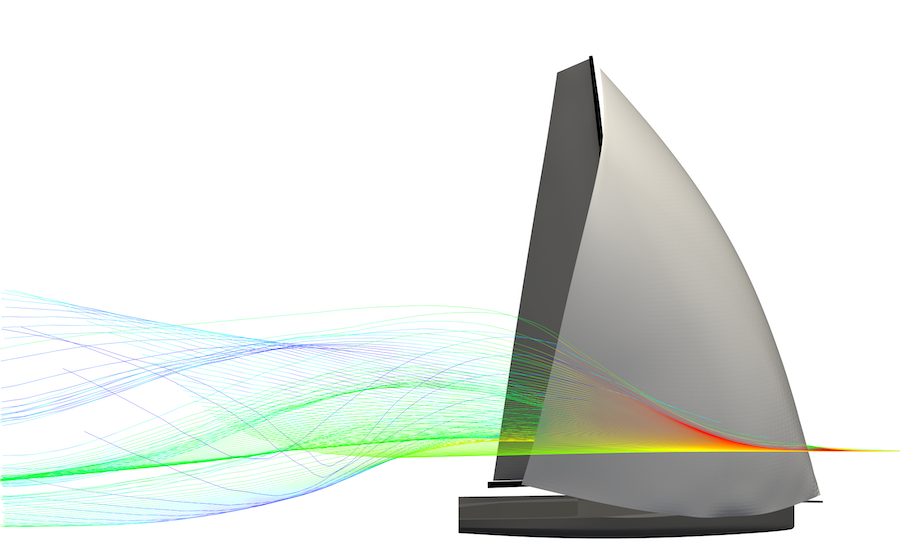

There has been a significant amount of hype and hyperbole about the development of headsails without furling torque-cables, and, like most good ideas, this concept has been around for a while. At North Sails their designers began working on this concept with Oracle Team USA and Emirates Team New Zealand during the 34th America’s Cup, when radical boat designs placed extreme loads on the 3Di headsails. The design and engineering challenge was to deliver a solution where headsail loads were redistributed from the torque cable/headstay and shared with the sail. Known within the North offices as Load Sharing Technology, this feature, when paired with a 3Di Helix Luff, is the North Sails answer to what others may call the cable-less headsail concept.

North Sails new Helix Luff technology transitions headsail loads out of a traditional anti-torsion cable and redistributes them, optimizing the load distribution throughout the sail and potentially reducing the overall loading. 📸North Sails / Ian Roman

North’s head of engineering and design JB Braun explains;

“Trying to reduce loads on boats and rigs while maintaining headstay tension has begun a trend and has opened up design ideas to rethinking the significance of luff cables, and in the case of Helix sails, to transition load out of a traditional anti-torsion cable and redistribute it into the sail.”

3Di technology is better suited to the sharing application because all 3Di sails are engineered with tapes laid in varying orientation and depth to optimize load distribution throughout the sail. 3Di’s intrinsic load sharing properties, coupled with a Helix Luff effectively move load reliance away from a cable/headstay and into the sail structure thus potentially reducing the overall loading.

“The critical breakthrough with Helix sails is that redistributed loads allow the headsail to project forward the structure on the front of the sail to achieve headstay tension and luff projection while reducing the load on the boat, mast, and rigging. The engineering emphasis is focused on the innovative, barely visible carbon Helix Luff structure, a 3Di design manipulation which projects the sail forward, punching the luff out in front of the boat.”

Load Sharing Technology coupled with the Helix Luff is empowering North to reimagine both roller furling downwind (Code Zero and A-3 style sails), reaching sails, and even may translate to some styles of upwind sails. It’s almost like another trim point. The 3Di technology paired with the powerful North Design Suite tools enables mapping and displacing loads to deliver lighter, more efficient, and beautifully smooth sails. North Helix sails are not aimed at one size or class of boat, but are suitable for most boats from mid-size IRC designs to TP52s, Imocas, Volvo Ocean Race boats, WallyCentos and 100-foot Maxis and even Superyachts.

Recent feedback from Steve Benjamin’s TP52 Spookie using North Helix sails was that they were recording about half the tack loads of a conventional Code Zero with similar or even better luff projection. This means less mast tip sag, less sideways sag, significantly less loading on the bowsprit, ropes, winches and deck gear… all with a sail that is projecting better and creating more forward driving force. Many of the loads on an existing boat are reduced – and for a new design, there is significant new potential for weight reduction throughout the entire boat.

North Sails Group president Ken Read expands, “Helix sails are the latest advancement of 3Di, a technology where North Sails focuses the majority of our R&D effort. We often move ahead without a great deal of fanfare because making lighter, and faster and more efficient sails is the bedrock of North Sails.”

“The big gains with Helix and Load Sharing Technology, especially on reaching and broad reaching furling sails, is overall weight reduction and the ability to really adjust the leading edge of the membrane’s shape with a very small luff cable or rope. Not the large and heavy Torque cables that have become commonplace. We are very excited as to all of the avenues that this has opened for the use of 3Di in this process.”

Above: TP52 Spookie. Using North Helix sails they have reduced the tack loads by half while also achieving more forward drive. This creates a lot of potential for weight reduction throughout the boat. 📸North Sails / Ian Roman

Ken Read, President, North Sails Group comments; “The beauty of North Sails is the amount of technology and software that goes into what we create. We made some new Helix Code Zeros in the summer when our brief was to be conservative. Now we are reaching into the finer details with our North Design Suite which allows us to map deeper into these same sails. The best part of being a part of this company is letting our smart people loose to go explore with our North Design Suite. This is a generational opportunity for using 3Di structure and how it all works; these sails will keep evolving and have already spread into non-furling sails, where load-sharing is going to potentially allow upwind headsails to have similar characteristics without the sideways sag. We believe that the North Helix sails are now lighter and faster than any other sail out there.”

“I can tell you that the new sails coming out now are nothing short of phenomenal! With any new concept, North Sails are always searching for a downside. Right now, we are aware that none of these new types of furling sail have been in the marketplace long enough to fully assess their true working life; we are also aware of longevity issues with sails from other manufacturers. That said, 3Di sails outlast the most extreme conditions, and of all the options, we’re confident 3Di will always stand up better than a mylar laminate.”

“What is important for us now is to cover all the bases with a focus on both performance and longevity. Our commitment is to a smoother sail that will furl and perform better than anything else out there. With North Helix sails, this is happening right now.”

Click here to request information about Helix Sails

READ MORE

READ MORE

news

DAVE LENZ TAKES ON THE MERLIN ROCKET

DAVE LENZ TAKES ON THE MERLIN ROCKET

Announcing Our One Design New Class Leader

As the Head of European Design for North Sails, Dave Lenz likes making sailboats go a little faster. He spends his workday with his “fingers in lots of pies,” developing sails for big boats like the TP52 and Fast 40. Now, on the weekends, he’ll be trying to make a Merlin Rocket go a little faster—with his wife as crew.

“She’s a good sailor,” he says. “She was keener than I was actually. It’s a personal sort of thing, just to go sailing and have some fun.”

Dave started sailing as a small child and then moved into Optimists and up through the British Youth Squad system. Olympic skiff sailing eventually led him to big boats, which led to a few jobs in sailmaking before he landed at North Sails in 2006.

“Back then, one design was in a separate building,” he remembers. “Now there’s less distinction, although with unique challenges.

Dave was a member of a top Melges 32 team in the late 2000s. “We won a European championship, and the combined winter championship at Key West, Miami, and Fort Lauderdale. Second and a third in Key West; good, solid results.”

Solid results in the Merlin Rocket will have to wait for more time in the boat. “We’ve only sailed it three times, and only one race,” he laughs. “Hit a top mark, the spinnaker sheets came untied…”

The Merlin Rocket appeals to Dave because it is a development class and tweaky enough to keep his interest. “You can work on sails or rig or foils for slightly different crew weights. There’s lots of controls to power up and depower the rig. And it isn’t as weight sensitive as some other classes.” Newer designs with less rig controls come and go, Dave says, because a lot of people like to be able to fiddle with their boat.

For a sail design expert, there’s also a fresh challenge written into the class rules.

“It has a combined sail area between mainsail and jib, so how you distribute the area between the two sails can vary. There’s definitely development to be done there. We’re also working on developing a 3Di mainsail, and longer term I think we’ll try a jib. The Merlin is a class that lends itself to that technology, and lessons we learn there will be very applicable to the rest of the things we do. It’s a good area for us to grow.”

Yet another appeal is fleet size and quality around the UK. “They have a seasonal circuit of open meetings, you’ll get between 30-60 boats at those events. National championships will be about 70-80 boats. Every year, there’s a regatta in Salcombe, a very nice town; they limit the entries to 120 boats. The boats are cool. And because it appeals to lots of good sailors, it appeals to lots more good sailors which means it is very competitive.”

Dave’s Recommended Inventory for 2019

A new mainsail model will launch very soon, Dave says. “We’re also looking at developing a larger jib than people have been using. That will be a good option, but doesn’t fit a lot of boats at this stage. You have to have a different measurement certificate, but it’s very feasible if it makes crews faster.” Dave is also focusing on other challenges to prepare for next season;

“We need to get a bit fitter. It’s a hiking boat, and there’s a bunch of youngsters that crew on these boats and they’re probably very fit.”